What are the Key Components of Agriculture Engineering Machines? | Q & A

Agricultural machinery is designed with several key components that work together to perform tasks efficiently. Understanding the basic working principles of these machines can help agricultural engineers and technical professionals optimize their use in the field.

1. Power SourcesMost agricultural machinery relies on external power sources to function, with the most common being:

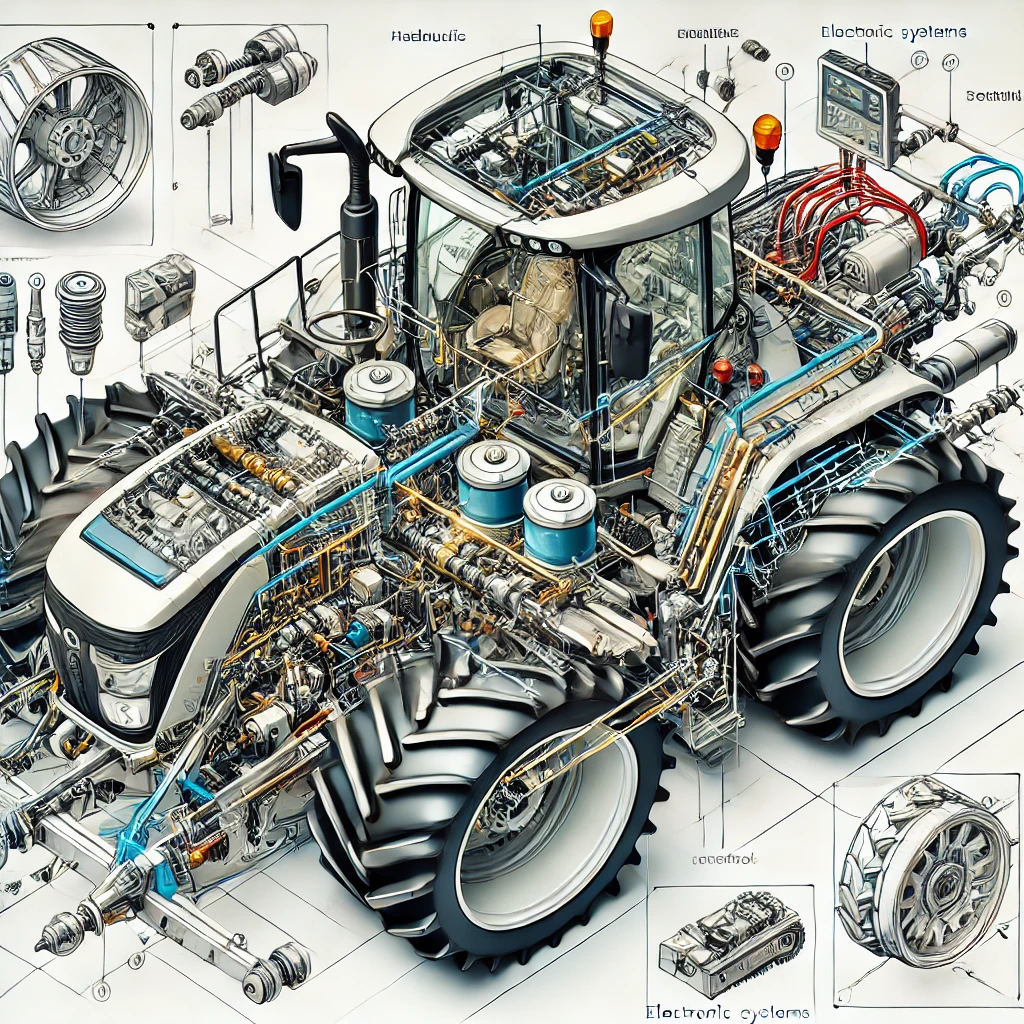

- Tractors: Tractors are the workhorses of agriculture, providing the power needed to operate a wide range of machinery such as plows, seeders, and harvesters. Tractors are equipped with power take-off (PTO) systems that transfer mechanical energy to attached implements.

- Electric Systems: Some modern machinery, especially those used for precision farming, are powered by electric motors. Electric systems are quieter, more energy-efficient, and are often found in smaller, lighter equipment used for specialized tasks like greenhouse farming.

- Hydraulic Systems: Many machines use hydraulic power to operate various moving parts. For instance, hydraulic lifts are used in harvesting machinery to lift and transport heavy loads like crops or bales. Hydraulic systems are valued for their precision and ability to exert great force.

Agricultural machinery has evolved from simple manual control to advanced, automated systems. Key control mechanisms include:

- Mechanical Controls: These are the simplest form of control, involving levers, pulleys, and gears. While still in use, especially in smaller or older equipment, mechanical controls require manual operation.

- Hydraulic Controls: Hydraulic control systems are widely used in modern machinery, allowing for smooth operation of moving parts like arms, blades, and conveyor belts. The fluid in these systems is pressurized and directed to actuators, creating motion.

- Electronic Controls: Advanced machinery uses electronic control systems to manage everything from steering to seeding depth. These systems often include sensors, GPS, and computerized controllers, making machines more accurate and efficient. For example, automatic steering systems in tractors allow for precise planting and tillage, reducing overlap and improving crop yields.

The integration of automation into agricultural machinery is one of the most significant advancements in modern farming. Automation allows machines to operate with minimal human intervention, leading to increased precision, reduced labor costs, and greater efficiency.

- GPS-Guided Tractors: GPS technology enables tractors and other machinery to follow exact paths across fields, optimizing fuel usage, reducing soil compaction, and ensuring that planting, fertilizing, and harvesting are done with high accuracy. This is especially beneficial in large-scale farming where even small inefficiencies can lead to significant losses.

- Autonomous Machinery: Some modern machinery, such as self-driving tractors and harvesters, can operate autonomously. These machines use sensors, cameras, and AI to navigate fields, monitor crop health, and perform tasks without the need for a driver. While still in development, autonomous systems have the potential to revolutionize agriculture by reducing the reliance on human labor.

Understanding the key components and working principles of agricultural machinery helps in the selection, maintenance, and optimization of these tools for specific farming needs. By choosing the right equipment and utilizing it effectively, farmers can maximize productivity while minimizing costs and environmental impact.