NisargDesai's Idea / Prospect

Sir Mokshagundam Visvesvaraya (commonly known as Sir M. Visvesvaraya) was one of India’s most revered engineers, scholars, and statesmen. He played a pivotal role in shaping modern India’s engineering landscape and is often regarded as a national hero for his numerous contributions to public welfare and nation-building.

Early Life and Education:

- Born: September 15, 1861, in Muddenahalli, a village in the Chikkaballapur district of Karnataka, India.

- Family: He came from a modest family; his father was a Sanskrit scholar and Ayurvedic practitioner. His father passed away when Visvesvaraya was still young, leading to financial hardships.

- Education: After completing his early education in Chikkaballapur, Visvesvaraya went to Central College, Bangalore, and later graduated in civil engineering from College of Engineering, Pune (then known as the Poona Engineering College) in 1883.

Major Contributions:

Engineering Projects:

- Krishna Raja Sagar Dam (KRS Dam): One of Visvesvaraya's most notable achievements, the KRS dam on the Cauvery River in Karnataka was built to provide irrigation and water supply to the Mysore state. It was considered one of the largest reservoirs in India at the time.

- Flood Control: He designed the automated floodgates installed at the Khadakwasla Dam near Pune. His flood control system was innovative for the time and prevented water wastage while efficiently managing water release, later implemented in various dams.

- Water Supply and Drainage Systems: He was responsible for improving water supply and sanitation systems in several cities across India, including Hyderabad and Aden (now part of Yemen).

Industrialization and Development:

- Economic Reforms in Mysore: As the Dewan of Mysore (1912–1918), Visvesvaraya transformed the state into a hub of industrialization. His work led to the establishment of the Mysore Soap Factory, Mysore Iron and Steel Works, and University of Mysore, among other initiatives.

- Bhadravati Iron and Steel Works: He was instrumental in setting up the Bhadravati Iron and Steel Works, one of India’s earliest industrial units.

Promotion of Technical Education:

- University of Mysore: In 1916, he helped establish the University of Mysore, promoting higher education and technical studies in the region.

- He consistently advocated for technical education, believing that a strong foundation in science and engineering was essential for India’s modernization.

Visionary Ideas:

- Public Administration: As a statesman, he implemented rigorous administrative reforms to make public institutions more efficient.

- Author: He authored several books, such as Reconstructing India and Planned Economy for India, where he emphasized the importance of planning, industrialization, and economic development for India's future.

Honors and Recognition:

- Bharat Ratna (1955): Visvesvaraya was awarded India's highest civilian honor in recognition of his immense contribution to public welfare and the field of engineering.

- Knight Commander of the British Indian Empire (KCIE, 1915): He was knighted by King George V in 1915 for his contributions to the public good.

- Institutes and Monuments: Several engineering institutions and public structures have been named after him, including the Visvesvaraya Technological University in Karnataka and the Visvesvaraya Industrial and Technological Museum in Bangalore.

Legacy:

Sir M. Visvesvaraya is remembered not only for his technical prowess but also for his vision of a self-reliant India. He believed in the power of knowledge, hard work, and engineering to transform society. His legacy as a pioneer in Indian engineering and a dedicated public servant is celebrated every year on his birthday, September 15, as Engineers' Day in India.

He passed away at the age of 101 on April 14, 1962. His life remains an inspiration for engineers and innovators worldwide.

To know about his vision and Philosophy of work follow the below link

September 15 is celebrated as Engineers' Day in honor of Sir Mokshagundam Visvesvaraya, one of the most distinguished engineers in Indian history. The date marks his birth anniversary. Sir M. Visvesvaraya was born on September 15, 1861, and his contributions to engineering, particularly in water resource management and infrastructure development, have had a lasting impact on the country.

Why Sir M. Visvesvaraya?

- Key Contributions: He was instrumental in several engineering projects, including the design and construction of dams, bridges, and irrigation systems. Notably, he designed the Krishna Raja Sagar Dam in Karnataka, which was considered a major engineering feat at the time.

- Innovative Mind: He is credited with inventing the automatic floodgates used in dams, which helped control water flow and prevent floods.

- Nation Builder: Beyond his technical achievements, Sir Visvesvaraya served as the Dewan (Prime Minister) of Mysore from 1912 to 1918. Under his leadership, Mysore transformed into one of the most progressive states in India.

For his contributions, he was awarded the Bharat Ratna in 1955, India’s highest civilian honor.

Thus, Engineers' Day on September 15 is a tribute to his enduring legacy and the role of engineers in the nation’s development.

Chemical engineering involves the application of chemistry, physics, and biology to produce materials and energy.

1. Alkali Production (1800 BCE)- Purpose: Used in ancient Egypt for soap making.

- Category: Industrial chemistry.

- Inventor: Nicolas Leblanc.

- Purpose: Industrial production of sodium carbonate (soda ash), used in glass and soap manufacturing.

- Category: Chemical process.

- Purpose: Separation of crude oil into components, leading to the modern petroleum industry.

- Category: Petrochemical.

- Inventor: Fritz Haber.

- Purpose: Industrial production of ammonia for fertilizers, revolutionizing agriculture.

- Category: Chemical process.

- Inventors: Reginald Gibson and Eric Fawcett.

- Purpose: One of the most commonly used plastics, essential in packaging and manufacturing.

- Category: Polymer chemistry.

- Inventor: Wallace Carothers (DuPont).

- Purpose: The first synthetic fiber, widely used in textiles and industry.

- Category: Polymer chemistry.

- Purpose: Improved process for refining petroleum into fuels and chemicals.

- Category: Petrochemical.

- Inventors: Herbert Boyer and Stanley Cohen.

- Purpose: Pioneering genetic engineering method for producing pharmaceuticals like insulin.

- Category: Biochemical engineering.

- Inventor: John Goodenough, Stanley Whittingham, Akira Yoshino.

- Purpose: Rechargeable batteries used in portable electronics and electric vehicles.

- Category: Electrochemical.

Electrical engineering covers the generation, transmission, and use of electrical power and systems.

1. Leyden Jar (1745 CE)- Purpose: Early form of a capacitor used to store static electricity.

- Category: Electricity storage.

- Inventor: Alessandro Volta.

- Purpose: The first chemical battery capable of producing a steady electrical current.

- Category: Power generation.

- Inventor: Michael Faraday.

- Purpose: Discovered the principle of electromagnetic induction, leading to the development of electrical generators and transformers.

- Category: Power generation.

- Inventor: Thomas Davenport.

- Purpose: Converts electrical energy into mechanical energy.

- Category: Electrical machines.

- Inventor: Werner von Siemens.

- Purpose: The first electrical generator capable of delivering power for industrial use.

- Category: Power generation.

- Inventor: Thomas Edison.

- Purpose: Practical electric light, revolutionizing residential and commercial lighting.

- Category: Electrical devices.

- Inventor: William Stanley.

- Purpose: Enabled the widespread use of alternating current (AC) for power distribution.

- Category: Power distribution.

- Inventor: John Bardeen, Walter Brattain, and William Shockley.

- Purpose: Semiconductor device used to amplify and switch electronic signals.

- Category: Electronics.

- Inventor: Jack Kilby and Robert Noyce.

- Purpose: Miniaturized electronic circuits on a single chip, revolutionizing electronics.

- Category: Electronics.

- Inventor: Intel.

- Purpose: The first commercial CPU, the Intel 4004, launched the era of modern computing.

- Category: Electronics and computing.

Civil engineering is one of the oldest engineering fields, focusing on infrastructure development like buildings, bridges, and water systems.

1. Irrigation Canals (~3000 BCE)- Purpose: Developed by ancient civilizations (e.g., Mesopotamians) for agricultural irrigation.

- Category: Water management.

- Purpose: Monumental tombs, showcasing advanced knowledge of construction and material use.

- Category: Structural engineering.

- Purpose: Defensive structure spanning thousands of kilometers.

- Category: Infrastructure.

- Purpose: Advanced water supply systems to transport fresh water to cities.

- Category: Hydraulic engineering.

- Purpose: The largest unreinforced concrete dome in the world, showcasing advancements in material engineering and structural design.

- Category: Structural engineering.

- Purpose: A Roman aqueduct bridge in France, demonstrating early civil engineering skills.

- Category: Hydraulic and structural engineering.

- Purpose: First steel-wire suspension bridge, a milestone in modern bridge engineering.

- Category: Structural and transportation engineering.

- Purpose: A major dam on the Colorado River, providing water and power to several states.

- Category: Hydraulic engineering.

- Purpose: Iconic suspension bridge that remains one of the longest and tallest.

- Category: Structural and transportation engineering.

- Purpose: Tallest man-made structure, pushing the limits of skyscraper engineering.

- Category: Structural engineering.

list of notable mechanical machines and tools, arranged in ascending order based on their approximate invention years.

1. Shaduf (~2000 BCE)

- Purpose: A lever-based irrigation tool used for lifting water, primarily in agriculture.

- Category: Agricultural.

2. Plow (~3000 BCE)

- Purpose: A farming tool for tilling the soil, one of the earliest mechanical agricultural tools.

- Category: Agricultural.

3. Water Wheel (~400 BCE)

- Purpose: Used in ancient Greece and Rome to harness water power for grinding grain and performing mechanical tasks.

- Category: Agricultural and Industrial.

4. Archimedes' Screw (~250 BCE)

- Purpose: A mechanical device for lifting water, used for irrigation.

- Category: Agricultural.

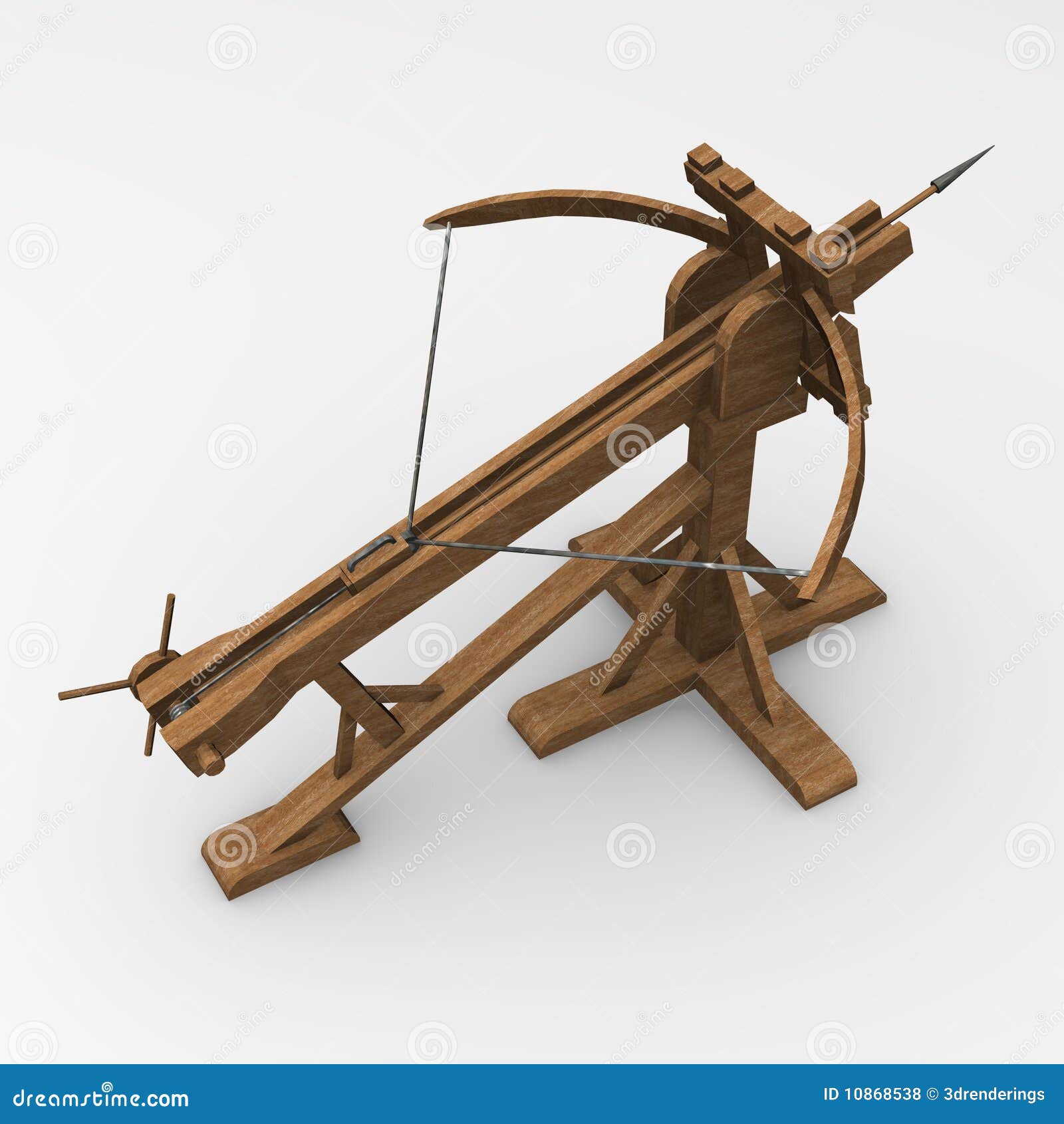

5. Catapult (~400 BCE)

- Purpose: A military machine used for launching projectiles in battle.

- Category: Military.

6. Ballista (~400 BCE)

- Purpose: An ancient missile weapon, similar to a large crossbow, for military use.

- Category: Military.

7. Windmill (~500-900 CE)

- Purpose: A mechanical device to harness wind power for grinding grain or pumping water.

- Category: Agricultural and Industrial.

8. Spinning Wheel (~1000 CE)

- Purpose: A tool for spinning thread or yarn from natural fibers, significantly improving textile production.

- Category: Textile.

9. Mechanical Clock (~1300 CE)

- Purpose: Used to measure time with increased precision, widely installed in public spaces.

- Category: Common use, scientific.

10. Printing Press (1440 CE)

- Inventor: Johannes Gutenberg.

- Purpose: Revolutionized the production of books and the dissemination of information through mechanical printing.

- Category: Industrial.

11. Flying Shuttle (1733 CE)

- Inventor: John Kay.

- Purpose: A key development in the textile industry, it sped up the weaving process in looms.

- Category: Textile.

12. Spinning Jenny (1764 CE)

- Inventor: James Hargreaves.

- Purpose: A multi-spindle spinning frame, dramatically increasing the production of yarn.

- Category: Textile.

13. Water Frame (1769 CE)

- Inventor: Richard Arkwright.

- Purpose: A water-powered spinning machine that was crucial for mechanizing the textile industry.

- Category: Textile.

14. Spinning Mule (1779 CE)

- Inventor: Samuel Crompton.

- Purpose: Combined the features of the Spinning Jenny and the Water Frame, producing finer, stronger thread.

- Category: Textile.

15. Steam Engine (1698-1712 CE)

- Inventor: Thomas Savery (1698), improved by Thomas Newcomen (1712) and James Watt (1765).

- Purpose: Used for pumping water, powering textile mills, and eventually revolutionizing transportation.

- Category: Industrial, transportation.

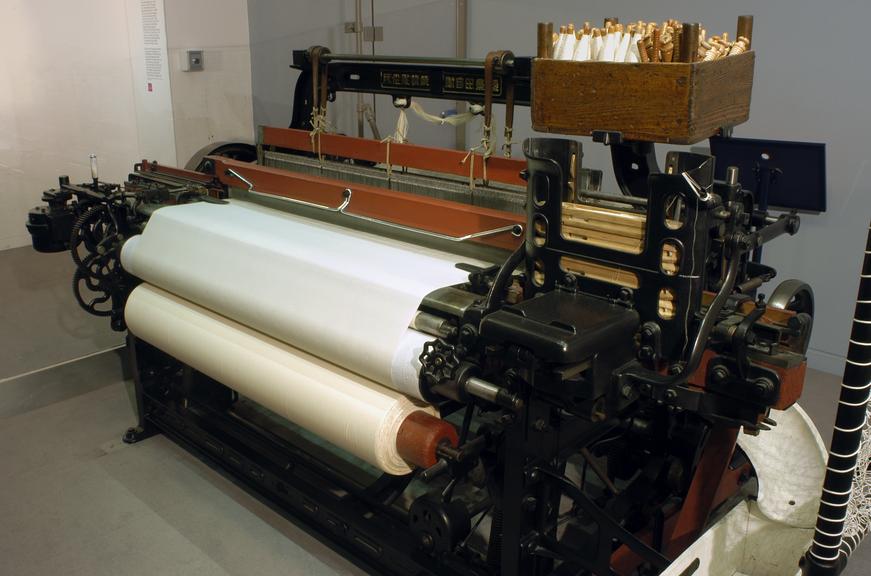

16. Power Loom (1785 CE)

- Inventor: Edmund Cartwright.

- Purpose: A mechanized loom that revolutionized the weaving process, contributing to the rise of factory-based textile production.

- Category: Textile.

17. Lathe (~1500 CE, modern lathe in 1750s)

- Purpose: A machine tool for shaping wood or metal, used in various industries including textiles for creating components.

- Category: Industrial.

18. Jacquard Loom (1804 CE)

- Inventor: Joseph Marie Jacquard.

- Purpose: Introduced a punch-card system to control the weaving of complex patterns in textiles, an early precursor to programming.

- Category: Textile.

19. Treadle-Powered Sewing Machine (1830 CE)

- Inventor: Barthelemy Thimonnier.

- Purpose: Mechanized sewing, revolutionizing garment manufacturing.

- Category: Textile, domestic.

20. Steam Locomotive (1804 CE)

- Inventor: Richard Trevithick.

- Purpose: Powered by steam engines, it transformed transportation and logistics.

- Category: Transportation.

21. Internal Combustion Engine (1876 CE)

- Inventor: Nikolaus Otto.

- Purpose: Powered automobiles and machinery, driving the transportation revolution.

- Category: Industrial, transportation.

22. Automobile (~1886 CE)

- Inventor: Karl Benz.

- Purpose: The first practical gasoline-powered car.

- Category: Transportation.

23. Airplane (1903 CE)

- Inventor: Wright Brothers.

- Purpose: The first powered flight, leading to modern aviation.

- Category: Transportation.

This timeline shows how early mechanical innovations in agriculture and military evolved into textile industry machines, which were a major part of the Industrial Revolution. Later, broader industrial machinery and transportation innovations took over, shaping the modern world.

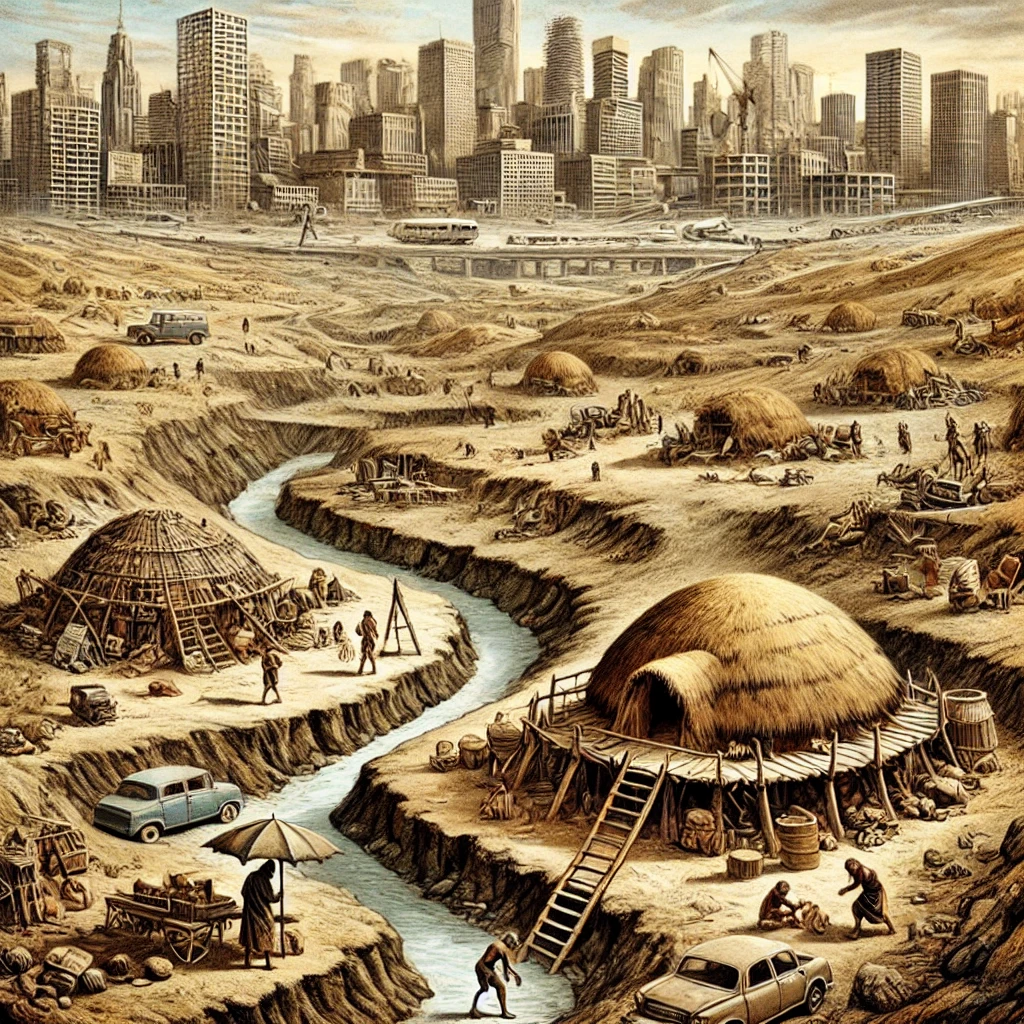

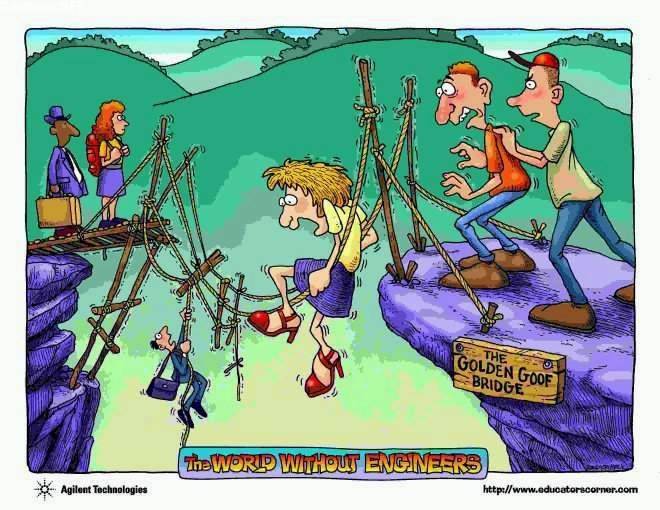

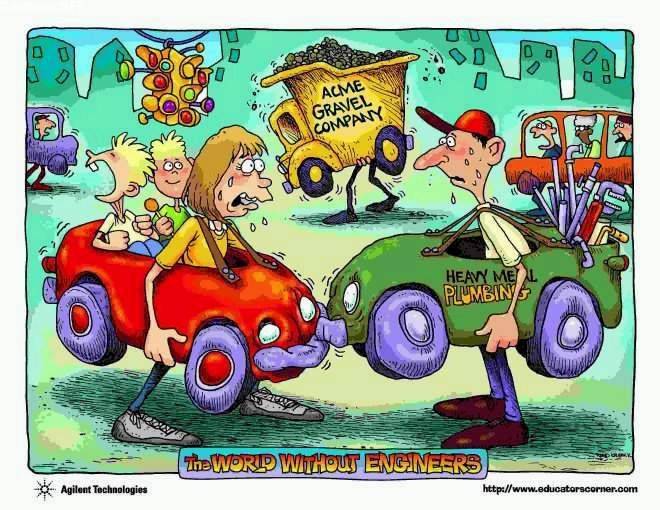

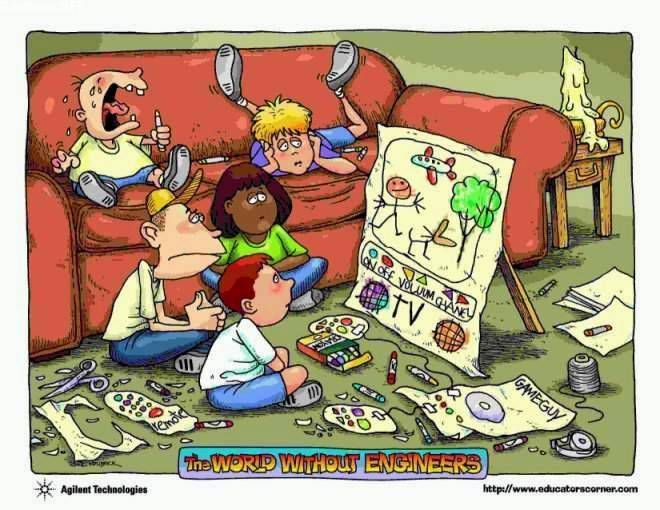

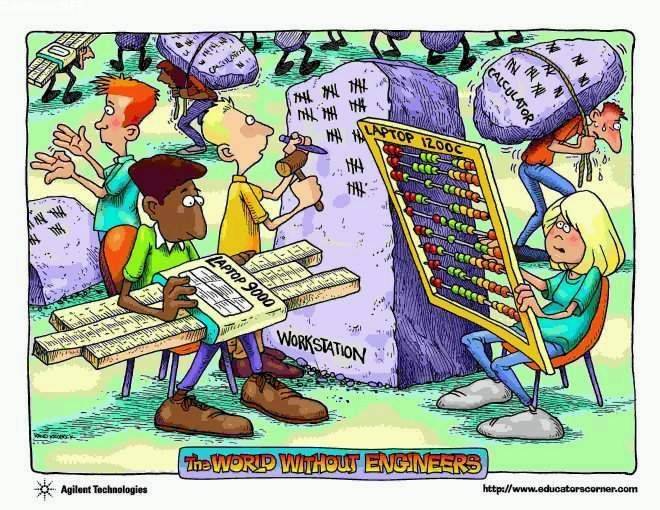

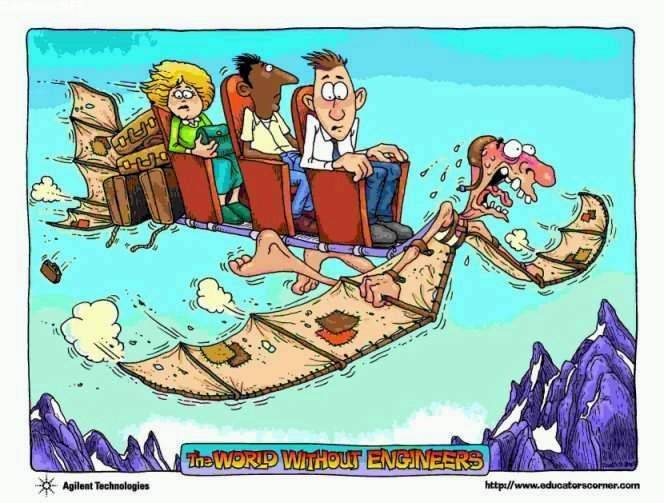

how life would be impacted without engineers from various specialized fields

- Infrastructure: Civil engineers design, build, and maintain essential infrastructure like roads, bridges, dams, and buildings. Without them, our transportation networks would be rudimentary, buildings less safe, and urban planning chaotic.

- Water Resources: Civil engineers also handle water supply and sanitation systems. Without them, clean water would be scarce, and sanitation could be a major public health crisis.

- Urban Development: City planning and the development of sustainable communities would be hindered, leading to overcrowded and poorly organized living spaces.

- Machinery and Automation: Mechanical engineers design and develop machines used in industries, transport, and everyday life. Without them, there would be no cars, trains, or airplanes, and industrial processes would be inefficient and labor-intensive.

- Energy Systems: Mechanical engineers also work on power generation systems like turbines and engines. Without them, our ability to generate and efficiently use energy would be severely limited.

- Consumer Products: From home appliances to fitness equipment, many everyday items would be unavailable or far less effective.

- Power Generation and Distribution: Electrical engineers design and maintain the systems that generate and distribute electricity. Without them, we’d lack reliable power, leading to a return to pre-electricity lifestyles.

- Communication Systems: Electronics engineers develop the technology behind phones, computers, and the internet. Without their work, global communication would be nearly impossible.

- Automation and Control Systems: Modern factories and homes rely on automation for efficiency. Without these engineers, production and daily life would be far less efficient.

- Computing Devices: Computer engineers are behind the development of hardware and software that powers computers, smartphones, and other digital devices. Without them, we’d be without modern computing, crippling almost every industry.

- Networking and Internet: They also design the systems that make the internet possible. Without these, global connectivity and access to information would be severely restricted.

- Artificial Intelligence and Robotics: Advancements in AI and robotics, which are revolutionizing industries, wouldn’t exist without computer engineers.

- Pharmaceuticals: Chemical engineers are crucial in the production of medicines. Without them, the development and mass production of life-saving drugs would be impossible.

- Petroleum and Energy: They also work in refining petroleum and developing alternative energy sources. Without them, fuel would be less accessible, and energy innovation would stagnate.

- Food Processing: The food we eat often requires processing to be safe and palatable. Chemical engineers ensure that food products are safe, nutritious, and efficiently produced.

- Aviation: Aerospace engineers design and develop aircraft. Without them, air travel wouldn’t exist, drastically limiting global mobility.

- Space Exploration: They are also responsible for spacecraft and satellite technology. Without aerospace engineers, humanity’s exploration of space and our understanding of the universe would be non-existent.

- Defense: Many defense systems, including missiles and surveillance drones, rely on aerospace engineering. Without this expertise, national security could be compromised.

- Medical Devices: Biomedical engineers design and develop medical devices like pacemakers, MRI machines, and prosthetics. Without them, diagnosing and treating many conditions would be much harder or impossible.

- Tissue Engineering: Advances in tissue engineering and regenerative medicine are spearheaded by biomedical engineers. Without them, treatments that restore or replace damaged tissues wouldn’t be available.

- Healthcare Innovation: The continuous improvement of healthcare technologies, leading to better patient outcomes, depends heavily on biomedical engineers.

- Pollution Control: Environmental engineers develop systems to reduce pollution and manage waste. Without them, air, water, and soil contamination would be far worse, endangering human health and ecosystems.

- Sustainable Development: They also work on projects that aim to balance development with environmental protection. Without their expertise, sustainability efforts would falter, leading to resource depletion and ecological crises.

- Renewable Energy: Environmental engineers are key in developing and implementing renewable energy solutions, crucial for combating climate change. Without them, the transition away from fossil fuels would be significantly slower.

- Manufacturing Efficiency: Industrial engineers optimize production processes, ensuring that goods are made efficiently and cost-effectively. Without them, manufacturing would be slower, more expensive, and less reliable.

- Supply Chain Management: They also manage supply chains, ensuring that products are delivered on time and at the right cost. Without industrial engineers, logistics would be chaotic, leading to shortages and inefficiencies.

- Quality Control: Ensuring that products meet quality standards is another key role. Without industrial engineers, product defects would be more common, affecting safety and customer satisfaction.

- Advanced Materials: Materials engineers develop new materials with specific properties for various applications. Without them, innovations in electronics, construction, and healthcare (like biodegradable implants) would be impossible.

- Metallurgy: They also work on the extraction and processing of metals. Without them, we would lack the materials needed for building infrastructure, manufacturing tools, and producing electronics.

- Nanotechnology: Advancements in nanotechnology, leading to innovations in fields like medicine, electronics, and energy, are driven by materials engineers. Without them, many cutting-edge technologies would not exist.

- Farm Equipment: Agricultural engineers design and develop machinery used in farming. Without them, modern farming methods wouldn’t be possible, leading to less food production and higher food prices.

- Irrigation and Water Management: They also design systems for efficient water use in agriculture. Without these systems, crop yields would be lower, and water resources could be wasted.

- Sustainable Farming Practices: Agricultural engineers are involved in developing sustainable farming practices to ensure food security. Without them, agriculture would struggle to meet the demands of a growing population.

- Shipbuilding: Marine engineers design and maintain ships and submarines. Without them, maritime trade and naval defense would be greatly diminished.

- Offshore Engineering: They also work on offshore structures like oil rigs and wind farms. Without marine engineers, exploiting marine resources and developing offshore energy would be nearly impossible.

- Oceanographic Technology: Marine engineers contribute to technologies that explore and monitor the ocean. Without their work, our understanding and stewardship of marine environments would be limited.

- Soil and Rock Mechanics: Geotechnicalengineers study the behavior of earth materials. Without them, constructing stable foundations for buildings, bridges, and tunnels would be much riskier.

- Landslide and Earthquake Mitigation: They also develop solutions to mitigate landslides and earthquake impacts. Without geotechnical engineers, many areas would be unsafe for habitation.

- Mining Engineering: Extraction of minerals and resources from the earth is guided by geotechnical principles. Without these engineers, mining would be far less efficient and more dangerous.

Without engineers from these specialized faculties, the world would lack the technological advancements, infrastructure, and innovations that make modern life possible. Society would struggle with basic needs like shelter, transportation, healthcare, and communication, resulting in a world that is less safe, less connected, and less prosperous.

Image Describes Human Civilization WIth and Without Engineers and all the advancement through them

Life without engineers would be drastically difficult, as engineers play a critical role in shaping the world we live in. Here are some key aspects that would be affected:

Infrastructure: Cities would lack the essential infrastructure like bridges, roads, tunnels, and buildings. The absence of civil engineers would mean no skyscrapers, efficient transportation systems, or safe residential structures.

Technology: Without engineers, technological advancements would be minimal. Computers, smartphones, and the internet—integral to modern communication—wouldn't exist.

Energy: Our energy systems, from electricity grids to renewable energy technologies like solar panels and wind turbines, rely heavily on engineers. Without them, reliable power supply and modern conveniences like electric lighting and heating would be unavailable.

Healthcare: Medical devices, diagnostic equipment, and pharmaceutical production processes, all designed and maintained by biomedical and chemical engineers, would be non-existent. This would significantly hinder medical progress and healthcare quality.

Transportation: Cars, airplanes, trains, and ships, all products of mechanical and aerospace engineering, would not exist. Travel would be limited to primitive methods, drastically slowing down global mobility.

Manufacturing: The production of goods, from food processing to electronics, relies on sophisticated machinery and automation designed by engineers. The efficiency and scale of modern manufacturing would be impossible without their contributions.

Water and Sanitation: Engineers design systems to provide clean water and manage waste. Without these systems, public health would be severely compromised.

Communication: The development of telecommunication systems, including satellites and fiber optics, would stall without engineers, limiting global connectivity.

Engineers are the backbone of innovation and functionality in society. Their absence would result in a world where basic needs are hard to meet, and technological progress is stunted.

So thanks to all the engineers to make Human Civilization more wonderful, good and easy going with full of facility and luxury.

Long Live Engineering

Now before you readers get this to some other way I must want to admit that. Science itself is more than just a philosophy. Even without direct engineering applications, scientific research advances our understanding of the universe, which is valuable in its own right. Pure science often drives innovation by pushing the boundaries of knowledge, which engineers later translate into practical applications.

The relationship between science and engineering is symbiotic rather than hierarchical. Engineers rely on scientific discoveries to innovate, and scientists often depend on engineering tools and technologies to conduct research. For example, advances in materials science or biomedical research often require sophisticated engineering tools and techniques.

And like wise Scientific research often relies on advanced tools and instruments, many of which are developed by engineers. For instance, modern physics would be unimaginable without the sophisticated particle accelerators designed by engineers, which allow scientists to probe the fundamental nature of matter.

Many scientific fields, such as astronomy or genomics, generate vast amounts of data. Engineers develop the technologies—like telescopes, sequencing machines, and data processing software—necessary for collecting, storing, and analyzing this data, enabling scientific discoveries.

Engineering innovations frequently lead to new experimental techniques. For example, advancements in materials science, a branch of engineering, have allowed scientists to explore the properties of new materials, leading to discoveries in nanotechnology and quantum computing.

Science provides the theoretical foundation and discoveries that engineers use to develop new technologies, while engineering provides the tools, techniques, and innovations that enable scientific research to advance. Both fields are crucial for progress, and each drives the other forward, leading to the continuous evolution of knowledge and technology.

So Science and Engineering both are interdependent wise versa.

but still ...

Engineers are responsible for applying scientific principles to solve real-world problems. Science provides the foundational knowledge, but engineering turns that knowledge into practical solutions, such as technology, infrastructure, and systems that benefit society. Without engineering, scientific discoveries might remain theoretical concepts, with limited impact on everyday life.

Engineers bridge the gap between scientific theory and practical implementation. For instance, while scientists may understand the principles of electromagnetism, it’s engineers who design and build electrical grids, smartphones, and computers. This practical application is what transforms scientific ideas into tangible realities.

Engineering is crucial for innovation and technological progress. Many of the advancements we associate with modern science—such as medical devices, renewable energy systems, and communication technologies—are the result of engineering efforts to harness scientific discoveries.

So "Without Engineers, Science Is Just a Philosophy" is a significant truth.

so I wrote this article to dedicate my gratitude to all of the Engineers who work hard on big important project with knowing that their name probably not going to shine only money as per market norm they are going to get but still they did work harder and smarter to make sure project don't get failed.

Long Live Engineering.

- Description: These kits typically include components like gears, pulleys, levers, and inclined planes. They are used to demonstrate fundamental mechanical principles such as force, torque, motion, and energy transfer.

- Common Uses: Educational demonstrations, basic experiments in statics and dynamics.

- Tools and Components:

- Gears (spur, bevel, worm)

- Pulleys and belts

- Levers and fulcrums

- Inclined planes

- Springs and weights

- Ropes and strings

- Force gauges

- Screw sets and nuts

- Description: Kits designed to study the motion of mechanisms, including linkages, cams, gears, and various types of motion converters (linear to rotational, etc.).

- Common Uses: Analysis of motion, design of mechanical linkages, study of velocity and acceleration in mechanical systems.

- Tools and Components:

- Linkages (four-bar, slider-crank)

- Cams and cam followers

- Gears and gear trains

- Shafts and axles

- Bearings

- Rotary encoders

- Stopwatches

- Protractors and rulers

- Description: These kits may include components like heat exchangers, thermocouples, and various setups to study conduction, convection, and radiation. They are used to demonstrate and experiment with the principles of thermodynamics and heat transfer.

- Common Uses: Demonstrating laws of thermodynamics, studying energy conversion processes, heat transfer experiments.

- Tools and Components:

- Heat exchangers

- Thermocouples and thermometers

- Insulating materials

- Heating elements (electric heaters, Bunsen burners)

- Calorimeters

- Pressure gauges

- Fans and blowers (for convection experiments)

- Radiation plates and sensors

- Description: Kits that include components like pumps, turbines, pipes, and flow meters. They are used to study fluid flow, pressure, and fluid-structure interactions.

- Common Uses: Demonstrating Bernoulli’s principle, studying laminar and turbulent flow, analyzing fluid systems.

- Tools and Components:

- Pumps (centrifugal, positive displacement)

- Flow meters (Venturi, orifice plate, rotameter)

- Piping and tubing

- Manometers and pressure gauges

- Valves (gate, ball, check)

- Turbines (small-scale)

- Nozzles and diffusers

- Fluid reservoirs

- Description: These kits typically include motors, sensors, controllers, and structural components to build and program robots. They may also come with software for simulation and control.

- Common Uses: Designing and programming robots, studying kinematics, automation, and control systems.

- Tools and Components:

- Servo motors and DC motors

- Microcontrollers (Arduino, Raspberry Pi)

- Sensors (ultrasonic, infrared, light)

- Wheels and tracks

- Structural components (beams, plates, fasteners)

- Breadboards and jumper wires

- Battery packs and power supplies

- Programming cables

- Description: Kits that provide components such as servos, controllers, sensors, and feedback devices to study control theory and implement control systems.

- Common Uses: PID controller experiments, stability analysis, automation tasks.

- Tools and Components:

- PID controllers

- Servos and actuators

- Sensors (temperature, pressure, position)

- Control loops (analog and digital)

- Microcontrollers or PLCs

- Oscilloscopes

- Signal generators

- Relay modules and switches

- Description: Kits that allow the study of vibrational characteristics of mechanical systems. They typically include components for generating and measuring vibrations, such as accelerometers, mass-spring systems, and damping materials.

- Common Uses: Studying natural frequencies, damping, and resonance in mechanical structures.

- Tools and Components:

- Accelerometers

- Vibration motors

- Springs and masses

- Damping materials (rubber pads, foam)

- Frequency counters

- Shakers (vibration generators)

- Signal analyzers

- Tunable mass dampers

- Description: These kits may include samples of different materials, testing equipment (like hardness testers), and tools for analyzing material properties such as tensile strength, elasticity, and fracture toughness.

- Common Uses: Material testing, failure analysis, studying the properties of metals, polymers, and composites.

- Tools and Components:

- Universal Testing Machine (UTM) components

- Hardness testers (Rockwell, Brinell)

- Sample materials (metals, polymers, composites)

- Microscopes (optical)

- Strain gauges

- Impact testers

- Metallurgical mounts

- Fracture analysis tools

- Description: Kits that include components like gears, shafts, bearings, and fasteners to design and test mechanical assemblies and systems. They may also include CAD files for 3D modeling.

- Common Uses: Prototyping mechanical systems, studying load distribution, stress analysis, and design optimization.

- Tools and Components:

- Gears (spur, helical, worm)

- Shafts and keys

- Bearings (ball, roller)

- Fasteners (bolts, nuts, washers)

- Sprockets and chains

- Couplings (rigid, flexible)

- Belts and pulleys

- Tolerance gauges and calipers

- Description: Kits focused on the principles of energy conversion, including components like solar panels, wind turbines, and small-scale engines. They are used to study and experiment with converting energy from one form to another.

- Common Uses: Experiments in renewable energy, studying thermodynamic cycles, efficiency analysis.

- Tools and Components:

- Small solar panels

- Wind turbine models

- Electric generators and motors

- Thermoelectric generators

- Batteries and energy storage devices

- Inverters and converters

- Energy meters and sensors

- Thermal engines (Stirling, steam)

- Description: Small-scale CNC kits that include a computer-controlled milling machine or lathe, along with the necessary software and tooling. These kits are used to introduce students and hobbyists to CNC machining.

- Common Uses: Prototyping, precision machining, learning CNC programming.

- Tools and Components:

- CNC milling machine or lathe

- Cutting tools (end mills, drill bits)

- Tool holders and collets

- Workholding devices (clamps, vises)

- Coolant system (basic)

- CAD/CAM software

- G-code generator

- Safety glasses and gloves

- Description: Kits that include a 3D printer and materials like PLA, ABS, or resin. These kits are used for prototyping and studying the principles of additive manufacturing.

- Common Uses: Rapid prototyping, custom part manufacturing, studying additive manufacturing processes.

- Tools and Components:

- 3D printer (FDM or resin)

- Filament or resin material

- Build plate and adhesives

- Nozzles and extruders

- CAD software

- Calibration tools (bed levelers, gauges)

- Scrapers and cutters (for part removal)

- UV light (for resin curing)

- Description: These kits include pumps, cylinders, valves, and actuators to demonstrate hydraulic and pneumatic systems. They are used to study the principles of fluid power and control.

- Common Uses: Building and controlling fluid power systems, studying hydraulic and pneumatic actuators.

- Tools and Components:

- Hydraulic pumps and cylinders

- Pneumatic actuators and valves

- Hoses and fittings

- Pressure gauges

- Flow control valves

- Reservoirs

- Compressors

- Control panels (manual or automated)

- Description: Kits designed to explore renewable energy technologies, often including small-scale solar panels, wind turbines, and associated measurement tools.

- Common Uses: Experiments in renewable energy generation, studying energy efficiency, and sustainability.

- Tools and Components:

- Small wind turbine blades and generator

- Solar panels

- Inverters and charge controllers

- Battery packs

- Energy meters

- Load resistors (for testing)

- Mounting hardware

- Simulation software (optional)

- Description: Kits that simulate automotive systems, including components like small engines, transmissions, braking systems, and suspension models.

- Common Uses: Studying vehicle dynamics, engine performance, and automotive systems design.

- Tools and Components:

- Small-scale engines (gasoline, electric)

- Transmission models

- Suspension systems (springs, dampers)

- Braking systems (disk, drum)

- Steering mechanisms Models

- Differential models

- Diagnostic tools (multi-meters, OBD scanners)

- Fuel and exhaust systems (carburetors, mufflers)

These kits are valuable resources for hands-on learning, experimentation, and the application of mechanical engineering principles in real-world scenarios.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)