User Ideas / Prospects

Executive Summary:

The Indian engineering job market in 2025 is characterized by significant dynamism, primarily fueled by rapid technological advancements and sustained economic growth. This report provides a comparative analysis of the job market trends for five mainstream engineering branches in India: Civil Engineering, Electrical Engineering, Computer Engineering, Chemical Engineering, and Mechanical Engineering. The purpose of this analysis is to offer strategic insights for professionals navigating this evolving landscape. Key findings indicate that Computer Engineering currently exhibits the strongest growth and demand, largely due to the ongoing digital transformation across industries. Mechanical Engineering also presents substantial opportunities owing to its foundational role in a wide array of sectors. While Civil, Electrical, and Chemical Engineering demonstrate steady growth and demand within their respective domains, the impact of emerging technologies is a critical factor influencing the trajectory of all five branches. The strongest trends are observed in Computer Engineering, driven by the digital revolution, and in Mechanical Engineering, supported by its adaptability across diverse sectors. These trends are primarily attributed to rapid technological advancements in areas like Artificial Intelligence (AI), Machine Learning (ML), and automation, coupled with government initiatives such as Make in India and Skill India, and consistent industrial expansion.

Introduction:

The Indian economy is currently experiencing a phase of rapid expansion, with an increasing emphasis on technological advancement and infrastructure development, which has a direct and significant impact on the engineering sector. Engineering serves as a fundamental pillar of India's progress, driving innovation, the expansion of essential infrastructure, and overall technological progress. This report will focus on five mainstream engineering branches that are crucial to this development: Civil Engineering, which deals with infrastructure and construction; Electrical Engineering, concerned with power and electronics; Computer Engineering, specializing in software and information technology; Chemical Engineering, focused on processes and materials; and Mechanical Engineering, which encompasses design and manufacturing. The primary objective of this report is to provide a comprehensive and data-driven comparative analysis of the job market trends for these five engineering branches within India for the year 2025 and the near future. This analysis aims to equip professionals with the necessary insights to make informed decisions regarding their career paths. The report will cover key aspects for each branch, including the current level of demand, the projected growth rate, the primary industries that are actively hiring, the influence of emerging technologies, the specific skills and specializations that are in high demand, and the typical salary ranges for professionals at different stages of their careers. The information presented in this analysis is derived from a variety of recent industry reports, surveys conducted by job portals and educational institutions, and relevant government statistics

Comparative Analysis of Job Market Trends:

- Demand:

Currently, Computer Engineering and Mechanical Engineering exhibit the highest demand in India in 2025. The demand for Computer Engineering is significantly boosted by the thriving IT sector and the ongoing digital transformation across various industries, with over 82,000 job openings reported 14. Mechanical Engineering also experiences strong demand due to its fundamental role in a wide array of industries, particularly manufacturing, automotive, and aerospace 23. Civil Engineering demonstrates robust demand driven by extensive infrastructure projects 2, while Electrical and Chemical Engineering maintain steady demand across their respective sectors 6. The sheer volume of job openings in Computer Engineering suggests a quantitatively higher current demand compared to the more general descriptions of demand in other engineering fields.

- Projected Growth Rate:

Computer Engineering is projected to have the most significant growth rate in the near future, with an anticipated 22% increase in tech jobs 11and a 21.4% CAGR in the engineering software market 13. Civil Engineering also shows strong growth projections, with a CAGR of 7.8% for the market 1and an annual demand growth of 9% for professionals 2, with some estimates going as high as 25% annually 3. Electrical Engineering is expected to grow at around 5% annually in terms of employment 8, with a notable 12% projected annual growth in the electrical equipment manufacturing market 6. Mechanical Engineering's growth is projected to be in the range of 4-7% 24, while Chemical Engineering is expected to see an approximate annual growth of 8% in demand 19. The consistently higher growth rate projected for Computer Engineering indicates that it will likely continue to generate more new job opportunities compared to the other branches in the coming years.

Key Industries:The primary industries actively hiring professionals vary across the engineering branches. Computer Engineering is heavily concentrated in the IT services sector, software development companies, and the e-commerce industry. Mechanical Engineering has the broadest distribution, with significant hiring in manufacturing, automotive, aerospace, and the energy sector. Civil Engineering is primarily focused on infrastructure and construction projects, with substantial involvement from the government sector. Electrical Engineering sees major hiring in power generation, telecommunications, and the automation industry. Chemical Engineering is vital for the chemical manufacturing and processing industries, including pharmaceuticals and the energy sector. The concentration of Computer Engineering in the rapidly expanding technology sector contrasts with the wider distribution of the other branches, suggesting different sensitivities to sector-specific economic fluctuations.

- Engineering Branch and Their Key Hiring Industries

Civil:-

Civil Services, Private Construction Firms, Indian Armed Forces, Public Sector Undertakings (PSUs), Infrastructure Development Companies

Electrical:-

Power Generation, Telecommunications, Automation & Robotics, Semiconductors, Renewable Energy, Electrical Equipment Manufacturing, Electronics Manufacturing

Computer:-

IT Services, Software Development, E-commerce, Artificial Intelligence and Machine Learning Companies, Product Development Companies, Cybersecurity Firms

Chemical:-

Oil & Gas, Chemical Manufacturing, Pharmaceuticals, Food Processing, Biotechnology, Petroleum, Fertilizer, Power and Energy, Water Treatment, FMCG, Air Conditioning and Refrigeration

Mechanical:-

Manufacturing, Automotive, Aerospace, Energy, Construction, Healthcare, Electronics, Pharmaceuticals, Heavy Machinery, Power Generation, Chemical Processing, Food and Beverage, Metals, Industrial Equipment, Machinery Manufacturing, Automation Systems, Consulting, Project Management

- Required Skills: While core engineering principles remain fundamental, all five branches increasingly demand digital literacy and skills related to emerging technologies. Computer Engineering professionals are expected to possess strong programming skills, expertise in cloud computing platforms, and knowledge of AI and ML tools. Mechanical Engineering requires proficiency in CAD software, understanding of automation and robotics, and knowledge of sustainable design principles. Civil Engineering professionals need skills in BIM software, knowledge of smart infrastructure technologies, and an understanding of sustainable construction practices. Electrical Engineering demands expertise in renewable energy systems, smart grid technologies, and embedded systems design. Chemical Engineering is focusing on skills related to process optimization, sustainable chemical processes, and biotechnology applications. This common need for digital skills across all engineering disciplines highlights a fundamental shift in the profession, where traditional domain expertise must be complemented by technological proficiency.

- Salary Expectations: In terms of salary expectations, Computer Engineering generally offers the highest compensation, particularly at the entry and mid-levels, owing to the intense demand within the rapidly expanding IT sector. Entry-level salaries in Computer Engineering can reach up to 11.8 LPA 11, and mid-level professionals often earn in excess of 10 LPA 14. Mechanical and Chemical Engineering also provide competitive salary packages, especially for mid-level and experienced professionals, with potential earnings reaching up to 12 LPA and 20+ LPA, respectively 21. Civil and Electrical Engineering offer good salary prospects as well, with entry-level positions ranging from 3-6 LPA and 4-6 LPA, respectively 8, and opportunities for higher earnings with specialization and increased experience. The salary premium observed in Computer Engineering reflects the intense competition for skilled talent within the rapidly growing technology industry in India.

- Typical Salary Ranges (LPA) by Engineering Branch and Experience Level

Civil:-

Entry Level ( 0-3 Years of Enperience):- 3.6 - 5.0

Mid Level( 3-7 Years of Enperience):- 5.0 - 7.5

Highly Experience Level ( 7+ Years of Experience):- 7.5 - 15 +

Electrical:-

Entry Level ( 0-3 Years of Enperience):- 3.0 - 4.5

Mid Level( 3-7 Years of Enperience):- 4.5 - 9.0

Highly Experience Level ( 7+ Years of Experience):-8.0 - 12+

Computer:-

Entry Level ( 0-3 Years of Enperience):- 6.0 - 11.8

Mid Level( 3-7 Years of Enperience):- 8.0 - 15.0

Highly Experience Level ( 7+ Years of Experience):-12.0 - 25+

Chemical:-

Entry Level ( 0-3 Years of Enperience):- 3.0 - 8.0

Mid Level( 3-7 Years of Enperience):- 5.0 - 10.0

Highly Experience Level ( 7+ Years of Experience):- 8.0 - 20+

Mechanical:-

Entry Level ( 0-3 Years of Enperience):- 3.0 - 6.0

Mid Level( 3-7 Years of Enperience):- 6.0 - 12.0

Highly Experience Level ( 7+ Years of Experience):- 12.0 - 20+

Comparative Analysis of Job Market Trends Across Mainstream Engineering Fields

1. Introduction

The engineering job market has undergone significant changes over the last five years, influenced by technological advancements, industry demand, and regional economic factors. This report provides a comparative analysis of job trends across key engineering disciplines globally and in India, backed by industry reports and expert analysis.

2. Overview of Engineering Fields Considered

Mechanical Engineering

Civil Engineering

Electrical Engineering

Electronics Engineering

Computer Science & Software Engineering

Chemical Engineering

Aerospace Engineering

3. Job Growth Trends (2019-2024)

Engineering FieldGlobal Job Growth (%)India Job Growth (%)Key Drivers

Mechanical +5% +6% Automation, Robotics, Renewable Energy (Source: World Economic Forum, Engineering Workforce Report 2023) Civil +3% +4% Urbanization, Smart Cities, Infrastructure Development (Source: India Infrastructure Report 2023) Electrical +4% +5% Power Grids, Renewable Energy, Electric Vehicles (EVs) (Source: International Energy Agency, Global Energy Outlook 2024) Electronics +2% +3% Consumer Electronics, Semiconductor Industry (Source: Semiconductor Industry Association 2023) Computer Science +12% +15% AI, Cloud Computing, Cybersecurity, Software Development (Source: Gartner IT Jobs Report 2024) Chemical +1% +2% Sustainable Materials, Green Chemistry, Pharmaceuticals (Source: Global Chemical Industry Report 2023) Aerospace +6% +7% Space Exploration, Defense, Private Aviation Growth (Source: NASA & ISRO Employment Reports 2023) 4. Key Findings & Comparative Analysis 4.1 Computer Science & Software Engineering

Highest Growth Rate due to demand in AI, ML, cybersecurity, and cloud technologies. (Source: McKinsey Digital Workforce Report 2024)

Remote Work Flexibility allows companies to hire globally, increasing competition.

India as an IT Hub has significantly contributed to its rapid job market expansion. (Source: NASSCOM India IT Jobs Report 2023)

4.2 Mechanical, Electrical, and Civil Engineering

Steady Growth but not as exponential as software fields. (Source: Bureau of Labor Statistics, Engineering Job Outlook 2024)

Automation & AI Integration is reshaping traditional roles.

Renewable Energy & EVs boosting opportunities in Electrical and Mechanical fields.

Smart Cities & Infrastructure Growth supporting Civil Engineering job demand. (Source: World Bank Infrastructure Investment Report 2023)

4.3 Electronics & Chemical Engineering

Slower Growth due to automation reducing manual design and manufacturing roles.

Semiconductor Industry Boom creating niche opportunities in Electronics. (Source: Semiconductor Industry Association 2023)

Sustainability Focus in Chemical Engineering opening new doors in green chemistry. (Source: Global Chemical Engineering Outlook 2024)

4.4 Aerospace Engineering

Stable to Growing Market with increased investments in private space exploration (SpaceX, ISRO, Blue Origin, etc.).

Defense & Commercial Aviation driving demand. (Source: Boeing & Airbus Industry Reports 2023)

5. Future Prospects & Emerging Trends

Interdisciplinary Skills: Engineers combining traditional skills with AI, IoT, and robotics will have a competitive edge. (Source: Harvard Business Review 2024)

Sustainability & Green Engineering: High demand in renewable energy, electric vehicles, and waste management.

Space & Defense Sector Expansion: Increasing aerospace engineering opportunities.

Upskilling & Reskilling: Engineers must adapt to digital transformations to remain relevant. (Source: LinkedIn Workforce Report 2023)

6. Conclusion

While Computer Science & Software Engineering leads in job market expansion, other engineering fields remain essential, with opportunities evolving due to technological shifts. Engineers who integrate software, automation, and sustainability into their expertise will have higher employability in the future.

Sources & References:

World Economic Forum, Engineering Workforce Report 2023

Bureau of Labor Statistics, Engineering Job Outlook 2024

NASSCOM India IT Jobs Report 2023

McKinsey Digital Workforce Report 2024

Semiconductor Industry Association 2023

Global Chemical Industry Report 2023

India Infrastructure Report 2023

International Energy Agency, Global Energy Outlook 2024

Boeing & Airbus Industry Reports 2023

NASA & ISRO Employment Reports 2023

Harvard Business Review 2024

LinkedIn Workforce Report 2023

This report provides a structured comparison of engineering job markets. Let me know if you need more detailed insights or additional data points!

Mechanical engineering has a great deal of breadth. It affects nearly every aspect of modern life. From the vehicles we drive to the machines that build our cities, this domain fuels innovation. However, did you know that mechanical engineering comes in different types? How many types of mechanical engineering are there?

Welcome back to Engineer’s Heaven, where we look at the various avenues that engineers can follow. If you’re considering a career in mechanical engineering—or you’re just curious—this guide will help you understand the seven major branches of this field.

Automotive Engineering

The branch of engineering that deals with the design, development and production of vehicles is known as automotive engineering. Automotive engineers design and manufacture vehicles with a focus on safety, speed, and efficiency. They design engines, refine aerodynamics, and develop new materials to make lighter vehicles.

Automotive engineers are in demand as we move toward electric and self-driving cars. They are instrumental in determining the future and direction of transport.

Aerospace Engineering

Aerospace engineering involves the design and development of aircraft, spacecraft and satellites. These engineers help planes fly safely and rockets reach space without wasting energy.

They develop aerodynamics, propulsion systems and lightweight materials. Aerospace engineering is an exciting and growth-oriented field with the advent of space travel and commercial aviation.

Manufacturing Engineering

Manufacturing engineering consists entirely about manufacturing. It relates to designing, developing and improving manufacturing processes. Engineers who work in this area ensure that products are produced efficiently and with high quality.

From assembly lines to 3D printing, they optimize manufacturing processes to minimize waste and maximize productivity. Manufacturing engineers are needed across industries to manufacture the products that companies sell.

Thermal Engineering

Thermal engineering is about heat and energy transfer. It is an essential consideration in the design of power plants, engines, and HVAC systems.

Engineers in this field focus on improving energy usage efficiency. They create advanced cooling systems for electronics, enhance storage of energy, and develop sustainable energy alternatives such as solar energy.

Mechatronics Engineering

Mechatronics is a combination of mechanical, electrical and computer engineering. It is specialized in Smart machine and automation system design.

“Think robotics, self-driving vehicles, sophisticated manufacturing solutions. Mechatronics engineers design intelligent machines that sense, process, and actuate. This field is fundamental for sectors such as robotics, medical devices, or industrial automation.

Marine Engineering

Marine engineers plan and maintain vessels, submarines, and offshore structures. They develop propulsion systems, fuel efficiency and ship safety.

This area is vital for international commerce since the majority of goods are moved by water. Marine engineers are addressing the requirement for cleaner and more efficient ships through hybrid propulsion and alternative fuel sources.

Structural Engineering

Structural engineering, though often associated with civil engineering, is also an essential component of mechanical engineering. It covers strong and durable structures of designed elements.

Mechanical engineers in this branch deal with mega projects such as bridges, buildings, and industrial plants. They help ensure that structures are able to tolerate stress, vibrations, and extreme weather events.

Why Mechanical Engineering?

Career Opportunities in Mechanical engineering never end. It combines creativity, problem-solving, and technical know-how. No matter if your passion lies in cars, aircraft, robotics, or even energy, there is a route for you.

Welcome to engineers heaven, the ultimate destination for all things engineering! So start now with us and begin your engineering journey.

Visit us at Engineer’s Heaven.

(Disclaimer: This statistics could be different in different part of World and Different timeline. this statistics has been generated based on data available till 2025 or relavant time span.)

Computational Fluid Dynamics (CFD) has really changed the analysis and

design fluid systems by the engineers. The fluid flow aspect is one of the

critical areas in the designing of mechanical equipment to be effective and

reliable. CFD solves complex fluid-related challenges that become an

indispensable tool for engineers; it enables engineers to simulate and

visualize fluid systems before making prototypes.

At Engineers Heaven, we always put emphasis on CFD in Mechanical Engineering. Be it designing industrial pumps, turbines, or HVAC systems, CFD

can help you enhance your design process. In this blog, we shall explore how

CFD is applied in fluid systems and equipment design.

What Is

Computational Fluid Dynamics?

CFD is a branch of fluid mechanics. It uses numerical analysis and

algorithms to simulate fluid flow. With CFD, engineers solve problems related

to fluid motion, heat transfer, and interactions with solid surfaces. It

combines physics, mathematics, and computer science to provide accurate

results.

CFD software subdivides the fluid space into tiny elements. With the

help of those elements, pressure, velocity, and temperature can be computed in

the system. It will provide an insight into flow patterns, thereby indicating

any issues in the design.

Why to Apply CFD

in Design?

Traditional analysis methods for fluids take much time. Prototypes for

testing take time and money to prepare. The application of CFD provides an

inexpensive approach. Detailed insight without actual physical testing at early

stages can be derived.

CFD saves time, cuts costs, and is more accurate. Engineers can test

different designs under different conditions. They can also optimize

performance to meet specific requirements.

Applications in

Fluid Systems

Fluid systems design involves the use of CFD widely. Below are some

key applications:

Pumps and

Turbines

CFD enables engineers to design energy-efficient pumps and turbines.

It analyzes flow patterns, pressure losses, as well as the risk of cavitation.

Engineers can modify designs for better efficiency and lower wear.

HVAC Systems

CFD optimizes airflow in heating, ventilation, and air conditioning

(HVAC) systems. It ensures uniform temperature distribution and improves energy

efficiency.

Piping Networks

Fluid flow in piping networks is complex. CFD identifies bottlenecks

and pressure drops. It helps optimize the layout and size of pipes for smoother

flow.

Aerospace

Applications

In aerospace engineering, CFD improves aerodynamics and fuel

efficiency. Engineers use it to design jet engines, nozzles, and airfoils.

Automotive

Industry

CFD enhances vehicle performance. It optimizes cooling systems,

exhaust flow, and fuel injection. It also improves aerodynamics for better

speed and fuel efficiency.

Applications in

Equipment Design

CFD is equally valuable in equipment design. The engineers use it to

analyze and improve the performance of equipment. Here are some examples:

Heat Exchangers

Heat exchangers are critical in various sectors. CFD ensures effective

heat transfer and minimizes pressure losses.

Compressors and

Blowers

CFD helps design compressors and blowers with minimal energy loss. It

improves reliability and reduces noise levels.

Mixing Equipment

In chemical and food industries, mixing is a crucial process. CFD

optimizes the mixing equipment by analyzing the behavior of the fluid.

Valves and

Fittings

Fluid flow is regulated by valves. CFD ensures proper valve operation

by analyzing pressure and flow distribution.

Benefits of CFD

The following are the benefits that CFD offers to engineers:

●

Improved Performance: It uncovers wastes and

optimizes the operation of the system.

●

Cost Reduction: CFD helps to reduce the amount of

physical prototypes, which saves money.

●

Better Understanding: Engineers can understand

the flow behaviour and make decisions.

●

Fastest Design Cycle: It reduces the designing

stage by early detection of defects

Conclusion

CFD is a revolution in mechanical engineering. It enables the designer

to be accurate and quick while designing the fluid systems and equipment. In

CFD, engineers are able to analyze problems and design for improved

performance.

At Engineers Heaven, we always try to provide the right knowledge and

tools such as CFD to engineers. This site provides you with the information,

tools, and advice needed to achieve your goals.

Visit Engineer’s Heaven today and get more information about the

engineering tools, methods and new technologies. Make your design process

simple and take your engineering skills to the next level.

(Disclaimer: This statistics could be different in different part of World and Different timeline. this statistics has been generated based on data available till 2025 or relavant time span.)

.jpeg) The environment we live in today would be considered a wonder of the modern world. From the tallest building to the most advanced communication gadgets, from the most sophisticated health care equipment to the most efficient transport systems, Engineering is the unseen driving force behind the things we see. But this immense discipline is anything but homogeneous. It is divided into many subcategories, each dealing with different issues. Today, let’s explore the “Magnificent Five,” the first five important engineering concepts that form the groundwork of engineering.

The environment we live in today would be considered a wonder of the modern world. From the tallest building to the most advanced communication gadgets, from the most sophisticated health care equipment to the most efficient transport systems, Engineering is the unseen driving force behind the things we see. But this immense discipline is anything but homogeneous. It is divided into many subcategories, each dealing with different issues. Today, let’s explore the “Magnificent Five,” the first five important engineering concepts that form the groundwork of engineering.

1. Civil Engineering: Constructing the Framework of Society

Suppose there were no bridges to unite people, no dams controlling the flow of water, and buildings that would house people. This is the domain of Civil Engineering, the people who design and create our world. They plan, build, and even repair the infrastructure that forms the basis of our societies. Civil engineers design the basics of a functioning society: roads and bridges, transportation systems, and water treatment plants.

2. Mechanical Engineering: The Mechanics of Motion

Have you ever asked yourself how a car engine starts or how a robot arm moves with great accuracy? They are mechanical engineers, aren’t they? They are the designers of movement, constructing and creating objects of every description. Whether it is the micro gears of a wristwatch or the large turbines that generate electricity, Mechanical Engineering know how forces and movements can be used to create these wonders.

3. Electrical Engineering: Powering Our World

Try to picture life without electricity. No light, no communication, no electricity, no facilities. Electrical Engineering field`s engineers are the magicians that people do not see, but they keep on managing the flow of electrons in our lives. They conceive, create, and sustain electrical systems, at the micro level of the tiny circuits in a computer chip and at the macro level of the power distribution networks for cities. Their expertise covers the whole spectrum of power generation and transmission, electronics, and telecommunication.

4. Chemical Engineering: Turning the Natural Resources into the Products We Use Daily

Consider the range of goods we consume every day, starting with essential medications and ending with the plastic containers for our drinks. Petroleum, gas, and chemicals are the ingredients that Chemical Engineering turn into the products that enhance our lives; they are the modern-day alchemists. They plan and manage industrial operations; they are concerned with safety, productivity, and environmental impact within the food industry, the oil industry, and many other industries.

5. Industrial Engineering: The improvement of systems for efficiency

This is because, unlike other engineers who mainly design components of a system, Industrial Engineering look more into optimization. They assess and optimize work methods, structures, and procedures for the achievement of the most effective results. Industrial engineers are involved in everything from arranging the physical layout of factories to managing the flow of goods and services in all sectors of the economy.

Engineer's Heaven: Your Gateway to the Engineering Universe

This is just a glimpse of the whole wide world of these five major branches of engineering disciplines. Each one of them has a number of subcategories that embrace a wide range of topics and reflect the abilities of the participants. If you want to know more about engineering, then go to Engineer’s Heaven This site is a one-stop shop for articles, tutorials, projects, and advice for anyone interested in becoming an engineer. So whether you are an experienced engineer or a student interested in the subject, Engineer’s Heaven is your starting point into the expansive world of engineering!

The Magnificent Five are just the tip of the iceberg. Engineering is a rapidly developing field with new branches created to address the needs of the future world. Therefore, go further, investigate, and find the engineering area that will make you passionate! Still, the future is in the talented brains of the young engineers of the future, or the engineers of tomorrow.

Mechanical engineering has long been at the heart of industrialization, driving innovations that have transformed society and elevated standards of living worldwide. From the development of steam engines and industrial machinery to modern transportation systems and manufacturing processes, mechanical engineering has significantly contributed to economic growth and technological progress. However, the rapid pace of industrialization, which largely depended on mechanical engineering advancements, has also played a significant role in creating today’s environmental crisis.

The challenges of climate change, resource depletion, pollution, and loss of biodiversity are direct consequences of industrial practices that have prioritized profit and efficiency over sustainability. Mechanical engineers now face the urgent task of addressing these environmental problems while continuing to innovate. It is essential that they incorporate sustainable practices to mitigate the harmful effects of past industrial advancements. In this context, mechanical engineers are uniquely positioned to be key players in resolving the sustainability crisis.

How Mechanical Engineering-Based Industrialization Led to the Sustainability CrisisThe industrial revolution, powered by mechanical engineering innovations, dramatically increased human productivity and economic output. However, it also initiated a range of unsustainable practices that have had lasting consequences for the environment:

Fossil Fuel Dependence: The advent of steam engines and internal combustion engines revolutionized transportation and manufacturing, but they also entrenched society's reliance on fossil fuels like coal, oil, and natural gas. The burning of these fuels releases large quantities of carbon dioxide (CO₂) and other greenhouse gases (GHGs) into the atmosphere, leading to global warming and climate change. Mechanical engineering advancements in industrial machinery and vehicles, while highly efficient, have exacerbated this issue by increasing fossil fuel consumption.

Mass Production and Resource Depletion: Mechanical engineering innovations led to the creation of factories and mass production systems, enabling industries to produce goods on a large scale. However, this surge in production also meant increased consumption of raw materials such as metals, minerals, and fossil fuels. The extraction and processing of these materials are resource-intensive, leading to habitat destruction, biodiversity loss, and depletion of finite natural resources.

Pollution and Waste: Mechanical engineering advancements in manufacturing and industrial processes often led to the uncontrolled release of pollutants into the air, water, and soil. Factories and power plants emit toxic chemicals and particulate matter, contributing to air and water pollution, which harms both ecosystems and human health. Moreover, the rise of mass production has led to an increase in waste generation, much of which ends up in landfills or oceans, causing further environmental degradation.

Industrial Agriculture and Mechanized Farming: The development of agricultural machinery such as tractors, harvesters, and irrigation systems revolutionized food production. While these innovations increased agricultural yields, they also contributed to environmental problems like soil erosion, water depletion, and the overuse of synthetic fertilizers and pesticides. These chemicals often leach into water bodies, causing harm to aquatic life and polluting freshwater supplies.

The environmental crisis precipitated by industrialization calls for a new approach to mechanical engineering—one that prioritizes sustainability, resource efficiency, and the reduction of environmental impact. Several practices can help resolve the issues created by past engineering-based industrialization:

Shifting to Renewable Energy: One of the most effective ways to address the fossil fuel problem is by transitioning to renewable energy sources. Mechanical engineers are at the forefront of developing renewable energy technologies such as wind turbines, solar panels, and hydropower systems. By focusing on energy efficiency and optimizing the design of these systems, mechanical engineers can reduce society's reliance on fossil fuels and significantly lower greenhouse gas emissions.

Engineers can also contribute to energy storage solutions, such as designing efficient battery systems that store energy from renewable sources for use during periods of low energy generation. This shift will help create a more sustainable and resilient energy grid.

Designing for Energy Efficiency: Mechanical engineers can play a crucial role in making industrial processes and products more energy-efficient. In manufacturing, for instance, engineers can develop energy-efficient machinery, optimize production lines to reduce energy consumption, and adopt automation systems that minimize resource waste. By designing products that consume less energy throughout their lifecycle, mechanical engineers can significantly reduce the carbon footprint of industries and consumers alike.

Energy-efficient building systems, such as advanced HVAC systems and smart heating and cooling technologies, can also help reduce energy consumption in residential and commercial settings, contributing to lower emissions and greater energy conservation.

Adopting Circular Economy Principles: Circular design, which emphasizes reusing, repairing, and recycling materials, offers a powerful solution to resource depletion and waste generation. Mechanical engineers can design products with modular components that are easy to repair or upgrade, extending the life of products and reducing the need for raw materials. By developing machinery and systems that prioritize recyclability and minimize waste, engineers can help create closed-loop manufacturing systems that reduce the environmental impact of industrial production.

For example, designing parts for disassembly ensures that materials can be recovered and reused at the end of a product's life, rather than being discarded. Implementing these principles can greatly reduce the environmental footprint of both products and manufacturing processes.

Sustainable Manufacturing and Green Technologies: Manufacturing is one of the most energy- and resource-intensive sectors, but it also offers numerous opportunities for sustainability. Mechanical engineers can drive the adoption of green manufacturing practices that reduce emissions, conserve water, and minimize waste. Techniques such as additive manufacturing (3D printing), which produces minimal waste by building products layer by layer, can significantly improve resource efficiency.

Engineers can also explore using sustainable materials, such as biodegradable plastics or recycled metals, in product design and manufacturing. The development of clean technologies, such as energy-efficient industrial equipment, further supports efforts to make manufacturing processes greener and less harmful to the environment.

Decarbonizing Transportation: Transportation is a major source of carbon emissions, and mechanical engineers are instrumental in developing sustainable alternatives. Engineers can continue to advance the development of electric vehicles (EVs), improve the efficiency of electric motors, and design lightweight vehicle components that reduce energy consumption. The transition from gasoline-powered vehicles to electric or hydrogen-powered transportation will significantly reduce carbon emissions.

Additionally, mechanical engineers can work on improving public transportation systems, making them more efficient and accessible, which can reduce the number of private vehicles on the road and lower overall emissions.

Improving Industrial Water Usage: Industrial processes consume vast amounts of water, and mechanical engineers can address this issue by developing more efficient water management systems. Technologies such as closed-loop cooling systems, water recycling, and advanced filtration can reduce water consumption in factories and power plants. By designing systems that conserve water and minimize pollution, engineers can help protect freshwater ecosystems and reduce the environmental impact of industrial activities.

To effectively address the sustainability crisis, mechanical engineers must adopt practices that focus on long-term environmental health and resource conservation. Key practices include:

- Lifecycle Assessments (LCA): Engineers must evaluate the environmental impact of their designs from cradle to grave, ensuring that products are sustainable throughout their lifecycle—from raw material extraction to disposal.

- Eco-Friendly Material Selection: Using sustainable, recyclable, and renewable materials helps minimize environmental damage and resource depletion.

- Energy Audits: Conducting energy audits for industrial systems and processes allows engineers to identify areas for improvement and implement energy-saving measures.

- Embracing Green Certifications: Engineers should aim to design and implement systems that meet green certification standards such as LEED (Leadership in Energy and Environmental Design), ensuring their projects meet high sustainability benchmarks.

- Cross-Disciplinary Collaboration: Mechanical engineers can collaborate with environmental scientists, urban planners, and architects to create holistic solutions that integrate sustainability into infrastructure, technology, and urban development.

Conclusion: Resolving the Crisis Through Sustainable Mechanical Engineering

The environmental crisis caused by past mechanical engineering innovations demands a new approach to engineering—one rooted in sustainability, ethical responsibility, and long-term thinking. Mechanical engineers have a unique opportunity to lead the way in addressing the pressing issues of climate change, resource depletion, and environmental degradation. By embracing renewable energy, energy-efficient design, sustainable manufacturing, and circular economy principles, mechanical engineers can create solutions that not only drive technological progress but also protect the planet.

Sustainable mechanical engineering is not just about designing better machines—it’s about ensuring that the systems we build today will support a healthy, thriving planet for generations to come. By prioritizing sustainability in their work, mechanical engineers can help resolve the environmental crisis, ensuring that industrial advancements no longer come at the cost of the Earth’s well-being.

list of notable mechanical machines and tools, arranged in ascending order based on their approximate invention years.

1. Shaduf (~2000 BCE)

- Purpose: A lever-based irrigation tool used for lifting water, primarily in agriculture.

- Category: Agricultural.

2. Plow (~3000 BCE)

- Purpose: A farming tool for tilling the soil, one of the earliest mechanical agricultural tools.

- Category: Agricultural.

3. Water Wheel (~400 BCE)

- Purpose: Used in ancient Greece and Rome to harness water power for grinding grain and performing mechanical tasks.

- Category: Agricultural and Industrial.

4. Archimedes' Screw (~250 BCE)

- Purpose: A mechanical device for lifting water, used for irrigation.

- Category: Agricultural.

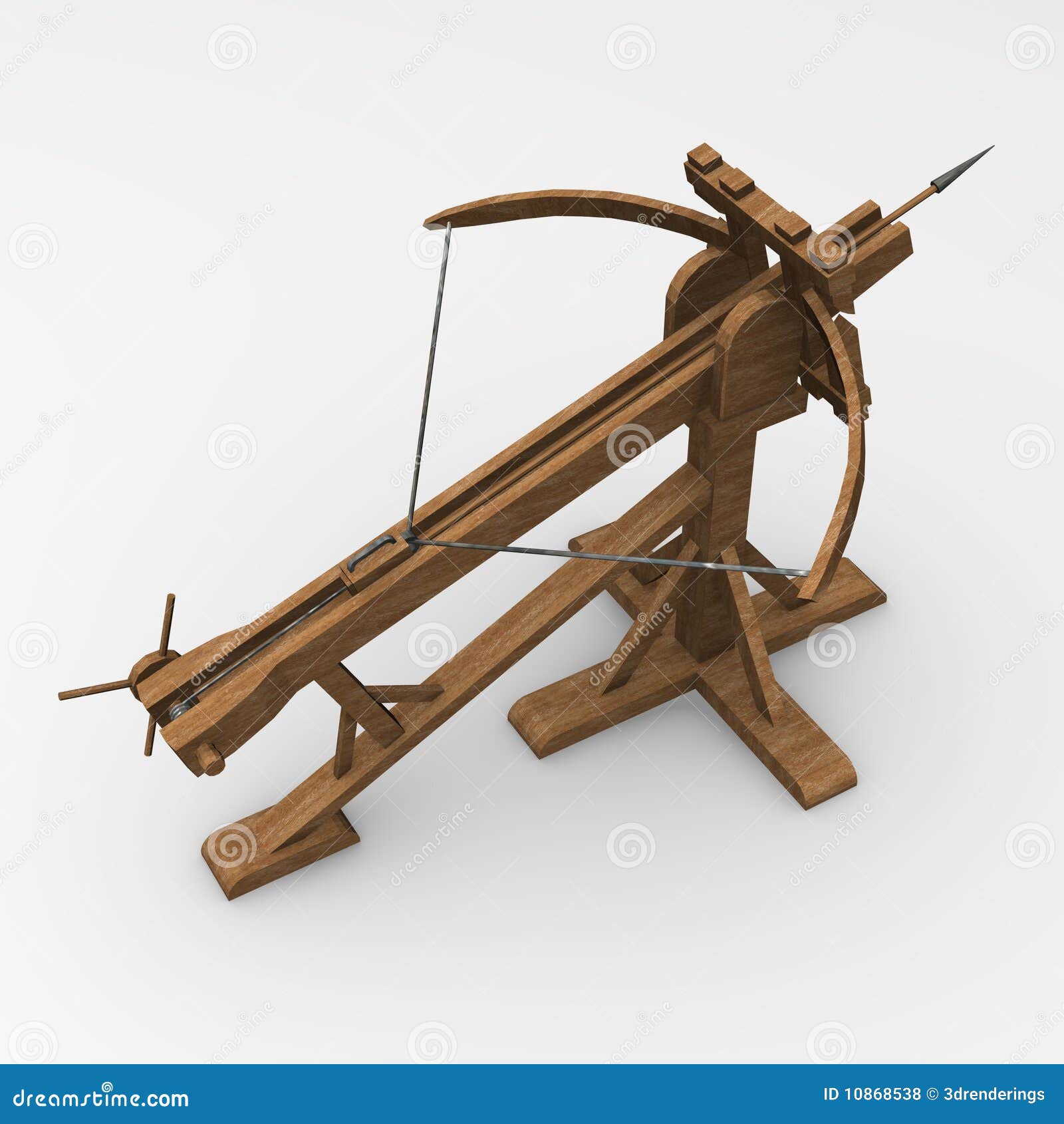

5. Catapult (~400 BCE)

- Purpose: A military machine used for launching projectiles in battle.

- Category: Military.

6. Ballista (~400 BCE)

- Purpose: An ancient missile weapon, similar to a large crossbow, for military use.

- Category: Military.

7. Windmill (~500-900 CE)

- Purpose: A mechanical device to harness wind power for grinding grain or pumping water.

- Category: Agricultural and Industrial.

8. Spinning Wheel (~1000 CE)

- Purpose: A tool for spinning thread or yarn from natural fibers, significantly improving textile production.

- Category: Textile.

9. Mechanical Clock (~1300 CE)

- Purpose: Used to measure time with increased precision, widely installed in public spaces.

- Category: Common use, scientific.

10. Printing Press (1440 CE)

- Inventor: Johannes Gutenberg.

- Purpose: Revolutionized the production of books and the dissemination of information through mechanical printing.

- Category: Industrial.

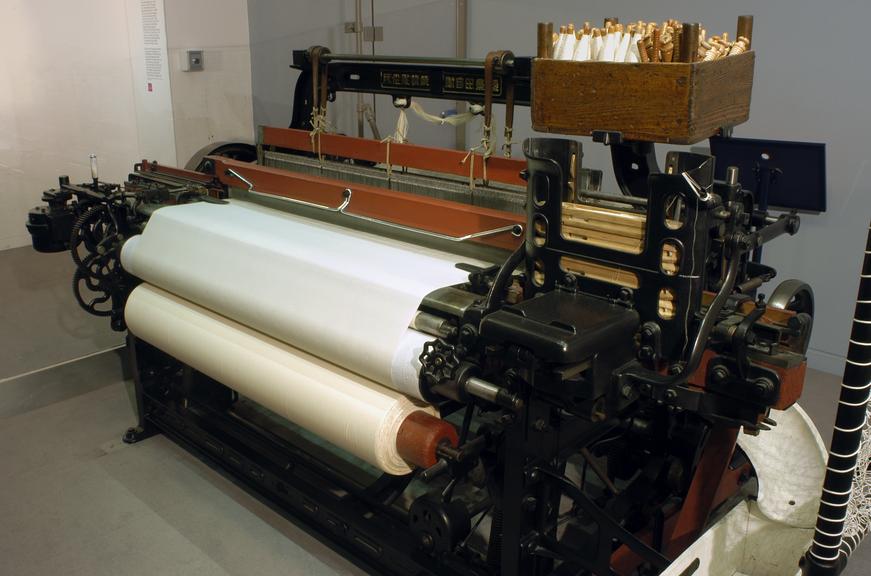

11. Flying Shuttle (1733 CE)

- Inventor: John Kay.

- Purpose: A key development in the textile industry, it sped up the weaving process in looms.

- Category: Textile.

12. Spinning Jenny (1764 CE)

- Inventor: James Hargreaves.

- Purpose: A multi-spindle spinning frame, dramatically increasing the production of yarn.

- Category: Textile.

13. Water Frame (1769 CE)

- Inventor: Richard Arkwright.

- Purpose: A water-powered spinning machine that was crucial for mechanizing the textile industry.

- Category: Textile.

14. Spinning Mule (1779 CE)

- Inventor: Samuel Crompton.

- Purpose: Combined the features of the Spinning Jenny and the Water Frame, producing finer, stronger thread.

- Category: Textile.

15. Steam Engine (1698-1712 CE)

- Inventor: Thomas Savery (1698), improved by Thomas Newcomen (1712) and James Watt (1765).

- Purpose: Used for pumping water, powering textile mills, and eventually revolutionizing transportation.

- Category: Industrial, transportation.

16. Power Loom (1785 CE)

- Inventor: Edmund Cartwright.

- Purpose: A mechanized loom that revolutionized the weaving process, contributing to the rise of factory-based textile production.

- Category: Textile.

17. Lathe (~1500 CE, modern lathe in 1750s)

- Purpose: A machine tool for shaping wood or metal, used in various industries including textiles for creating components.

- Category: Industrial.

18. Jacquard Loom (1804 CE)

- Inventor: Joseph Marie Jacquard.

- Purpose: Introduced a punch-card system to control the weaving of complex patterns in textiles, an early precursor to programming.

- Category: Textile.

19. Treadle-Powered Sewing Machine (1830 CE)

- Inventor: Barthelemy Thimonnier.

- Purpose: Mechanized sewing, revolutionizing garment manufacturing.

- Category: Textile, domestic.

20. Steam Locomotive (1804 CE)

- Inventor: Richard Trevithick.

- Purpose: Powered by steam engines, it transformed transportation and logistics.

- Category: Transportation.

21. Internal Combustion Engine (1876 CE)

- Inventor: Nikolaus Otto.

- Purpose: Powered automobiles and machinery, driving the transportation revolution.

- Category: Industrial, transportation.

22. Automobile (~1886 CE)

- Inventor: Karl Benz.

- Purpose: The first practical gasoline-powered car.

- Category: Transportation.

23. Airplane (1903 CE)

- Inventor: Wright Brothers.

- Purpose: The first powered flight, leading to modern aviation.

- Category: Transportation.

This timeline shows how early mechanical innovations in agriculture and military evolved into textile industry machines, which were a major part of the Industrial Revolution. Later, broader industrial machinery and transportation innovations took over, shaping the modern world.

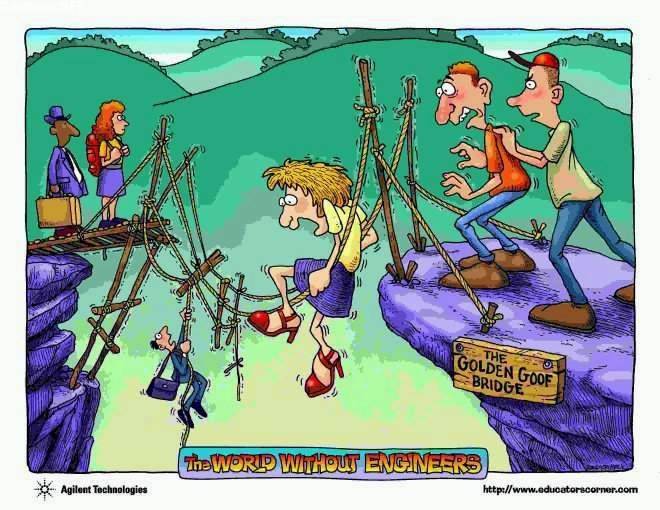

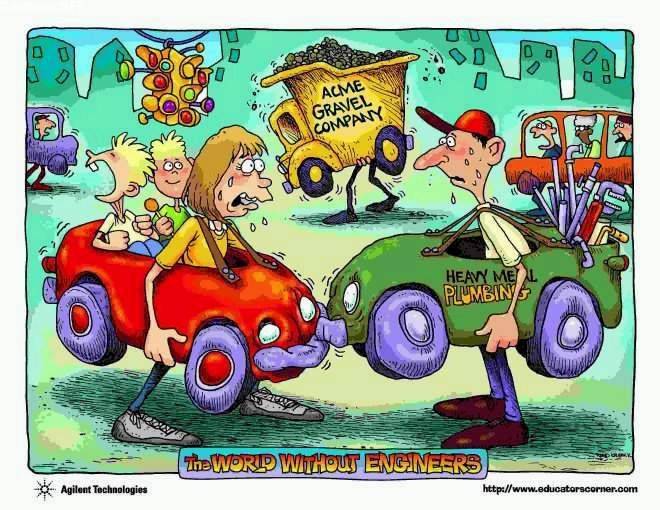

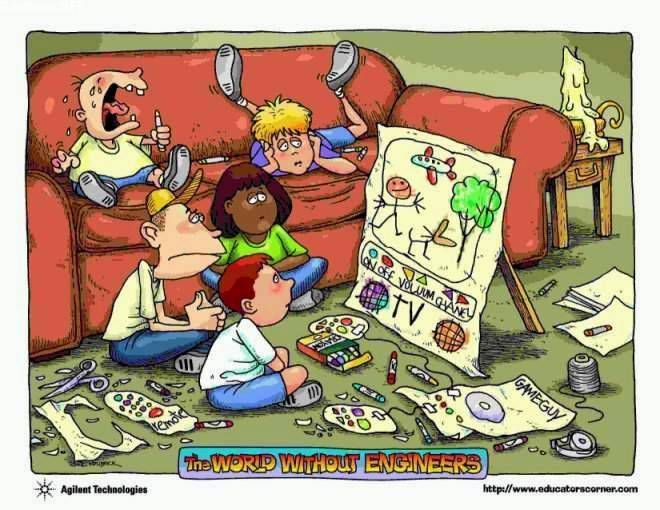

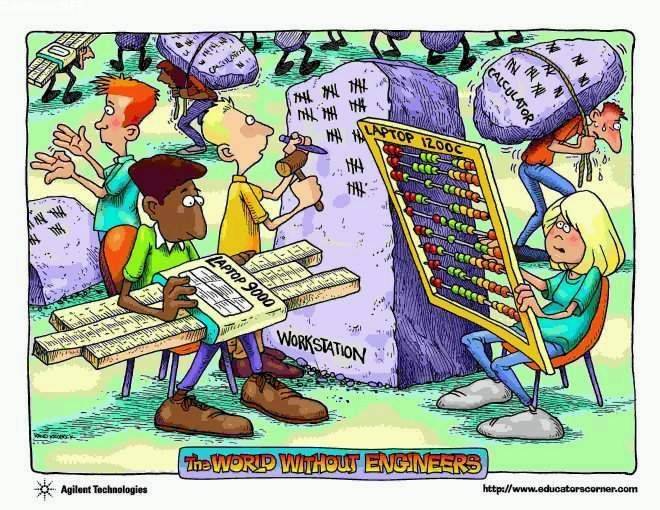

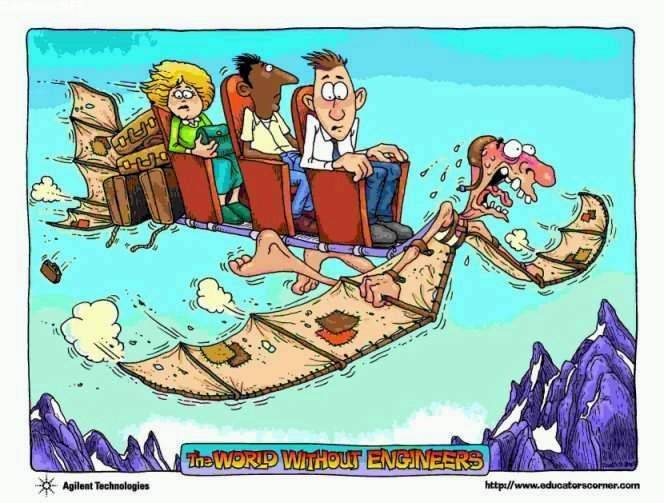

how life would be impacted without engineers from various specialized fields

- Infrastructure: Civil engineers design, build, and maintain essential infrastructure like roads, bridges, dams, and buildings. Without them, our transportation networks would be rudimentary, buildings less safe, and urban planning chaotic.

- Water Resources: Civil engineers also handle water supply and sanitation systems. Without them, clean water would be scarce, and sanitation could be a major public health crisis.

- Urban Development: City planning and the development of sustainable communities would be hindered, leading to overcrowded and poorly organized living spaces.

- Machinery and Automation: Mechanical engineers design and develop machines used in industries, transport, and everyday life. Without them, there would be no cars, trains, or airplanes, and industrial processes would be inefficient and labor-intensive.

- Energy Systems: Mechanical engineers also work on power generation systems like turbines and engines. Without them, our ability to generate and efficiently use energy would be severely limited.

- Consumer Products: From home appliances to fitness equipment, many everyday items would be unavailable or far less effective.

- Power Generation and Distribution: Electrical engineers design and maintain the systems that generate and distribute electricity. Without them, we’d lack reliable power, leading to a return to pre-electricity lifestyles.

- Communication Systems: Electronics engineers develop the technology behind phones, computers, and the internet. Without their work, global communication would be nearly impossible.

- Automation and Control Systems: Modern factories and homes rely on automation for efficiency. Without these engineers, production and daily life would be far less efficient.

- Computing Devices: Computer engineers are behind the development of hardware and software that powers computers, smartphones, and other digital devices. Without them, we’d be without modern computing, crippling almost every industry.

- Networking and Internet: They also design the systems that make the internet possible. Without these, global connectivity and access to information would be severely restricted.

- Artificial Intelligence and Robotics: Advancements in AI and robotics, which are revolutionizing industries, wouldn’t exist without computer engineers.

- Pharmaceuticals: Chemical engineers are crucial in the production of medicines. Without them, the development and mass production of life-saving drugs would be impossible.

- Petroleum and Energy: They also work in refining petroleum and developing alternative energy sources. Without them, fuel would be less accessible, and energy innovation would stagnate.

- Food Processing: The food we eat often requires processing to be safe and palatable. Chemical engineers ensure that food products are safe, nutritious, and efficiently produced.

- Aviation: Aerospace engineers design and develop aircraft. Without them, air travel wouldn’t exist, drastically limiting global mobility.

- Space Exploration: They are also responsible for spacecraft and satellite technology. Without aerospace engineers, humanity’s exploration of space and our understanding of the universe would be non-existent.

- Defense: Many defense systems, including missiles and surveillance drones, rely on aerospace engineering. Without this expertise, national security could be compromised.

- Medical Devices: Biomedical engineers design and develop medical devices like pacemakers, MRI machines, and prosthetics. Without them, diagnosing and treating many conditions would be much harder or impossible.

- Tissue Engineering: Advances in tissue engineering and regenerative medicine are spearheaded by biomedical engineers. Without them, treatments that restore or replace damaged tissues wouldn’t be available.

- Healthcare Innovation: The continuous improvement of healthcare technologies, leading to better patient outcomes, depends heavily on biomedical engineers.

- Pollution Control: Environmental engineers develop systems to reduce pollution and manage waste. Without them, air, water, and soil contamination would be far worse, endangering human health and ecosystems.

- Sustainable Development: They also work on projects that aim to balance development with environmental protection. Without their expertise, sustainability efforts would falter, leading to resource depletion and ecological crises.

- Renewable Energy: Environmental engineers are key in developing and implementing renewable energy solutions, crucial for combating climate change. Without them, the transition away from fossil fuels would be significantly slower.

- Manufacturing Efficiency: Industrial engineers optimize production processes, ensuring that goods are made efficiently and cost-effectively. Without them, manufacturing would be slower, more expensive, and less reliable.

- Supply Chain Management: They also manage supply chains, ensuring that products are delivered on time and at the right cost. Without industrial engineers, logistics would be chaotic, leading to shortages and inefficiencies.

- Quality Control: Ensuring that products meet quality standards is another key role. Without industrial engineers, product defects would be more common, affecting safety and customer satisfaction.

- Advanced Materials: Materials engineers develop new materials with specific properties for various applications. Without them, innovations in electronics, construction, and healthcare (like biodegradable implants) would be impossible.

- Metallurgy: They also work on the extraction and processing of metals. Without them, we would lack the materials needed for building infrastructure, manufacturing tools, and producing electronics.

- Nanotechnology: Advancements in nanotechnology, leading to innovations in fields like medicine, electronics, and energy, are driven by materials engineers. Without them, many cutting-edge technologies would not exist.

- Farm Equipment: Agricultural engineers design and develop machinery used in farming. Without them, modern farming methods wouldn’t be possible, leading to less food production and higher food prices.

- Irrigation and Water Management: They also design systems for efficient water use in agriculture. Without these systems, crop yields would be lower, and water resources could be wasted.

- Sustainable Farming Practices: Agricultural engineers are involved in developing sustainable farming practices to ensure food security. Without them, agriculture would struggle to meet the demands of a growing population.

- Shipbuilding: Marine engineers design and maintain ships and submarines. Without them, maritime trade and naval defense would be greatly diminished.

- Offshore Engineering: They also work on offshore structures like oil rigs and wind farms. Without marine engineers, exploiting marine resources and developing offshore energy would be nearly impossible.

- Oceanographic Technology: Marine engineers contribute to technologies that explore and monitor the ocean. Without their work, our understanding and stewardship of marine environments would be limited.

- Soil and Rock Mechanics: Geotechnicalengineers study the behavior of earth materials. Without them, constructing stable foundations for buildings, bridges, and tunnels would be much riskier.

- Landslide and Earthquake Mitigation: They also develop solutions to mitigate landslides and earthquake impacts. Without geotechnical engineers, many areas would be unsafe for habitation.

- Mining Engineering: Extraction of minerals and resources from the earth is guided by geotechnical principles. Without these engineers, mining would be far less efficient and more dangerous.

Without engineers from these specialized faculties, the world would lack the technological advancements, infrastructure, and innovations that make modern life possible. Society would struggle with basic needs like shelter, transportation, healthcare, and communication, resulting in a world that is less safe, less connected, and less prosperous.

- Description: These kits typically include components like gears, pulleys, levers, and inclined planes. They are used to demonstrate fundamental mechanical principles such as force, torque, motion, and energy transfer.

- Common Uses: Educational demonstrations, basic experiments in statics and dynamics.

- Tools and Components:

- Gears (spur, bevel, worm)

- Pulleys and belts

- Levers and fulcrums

- Inclined planes

- Springs and weights

- Ropes and strings

- Force gauges

- Screw sets and nuts

- Description: Kits designed to study the motion of mechanisms, including linkages, cams, gears, and various types of motion converters (linear to rotational, etc.).

- Common Uses: Analysis of motion, design of mechanical linkages, study of velocity and acceleration in mechanical systems.

- Tools and Components:

- Linkages (four-bar, slider-crank)

- Cams and cam followers

- Gears and gear trains

- Shafts and axles

- Bearings

- Rotary encoders

- Stopwatches

- Protractors and rulers

- Description: These kits may include components like heat exchangers, thermocouples, and various setups to study conduction, convection, and radiation. They are used to demonstrate and experiment with the principles of thermodynamics and heat transfer.

- Common Uses: Demonstrating laws of thermodynamics, studying energy conversion processes, heat transfer experiments.

- Tools and Components:

- Heat exchangers

- Thermocouples and thermometers

- Insulating materials

- Heating elements (electric heaters, Bunsen burners)

- Calorimeters

- Pressure gauges

- Fans and blowers (for convection experiments)

- Radiation plates and sensors

- Description: Kits that include components like pumps, turbines, pipes, and flow meters. They are used to study fluid flow, pressure, and fluid-structure interactions.

- Common Uses: Demonstrating Bernoulli’s principle, studying laminar and turbulent flow, analyzing fluid systems.

- Tools and Components:

- Pumps (centrifugal, positive displacement)

- Flow meters (Venturi, orifice plate, rotameter)

- Piping and tubing

- Manometers and pressure gauges

- Valves (gate, ball, check)

- Turbines (small-scale)

- Nozzles and diffusers

- Fluid reservoirs

- Description: These kits typically include motors, sensors, controllers, and structural components to build and program robots. They may also come with software for simulation and control.

- Common Uses: Designing and programming robots, studying kinematics, automation, and control systems.

- Tools and Components:

- Servo motors and DC motors

- Microcontrollers (Arduino, Raspberry Pi)

- Sensors (ultrasonic, infrared, light)

- Wheels and tracks

- Structural components (beams, plates, fasteners)

- Breadboards and jumper wires

- Battery packs and power supplies

- Programming cables

- Description: Kits that provide components such as servos, controllers, sensors, and feedback devices to study control theory and implement control systems.

- Common Uses: PID controller experiments, stability analysis, automation tasks.

- Tools and Components:

- PID controllers

- Servos and actuators

- Sensors (temperature, pressure, position)

- Control loops (analog and digital)

- Microcontrollers or PLCs

- Oscilloscopes

- Signal generators

- Relay modules and switches

- Description: Kits that allow the study of vibrational characteristics of mechanical systems. They typically include components for generating and measuring vibrations, such as accelerometers, mass-spring systems, and damping materials.

- Common Uses: Studying natural frequencies, damping, and resonance in mechanical structures.

- Tools and Components:

- Accelerometers

- Vibration motors

- Springs and masses

- Damping materials (rubber pads, foam)

- Frequency counters

- Shakers (vibration generators)

- Signal analyzers

- Tunable mass dampers

- Description: These kits may include samples of different materials, testing equipment (like hardness testers), and tools for analyzing material properties such as tensile strength, elasticity, and fracture toughness.

- Common Uses: Material testing, failure analysis, studying the properties of metals, polymers, and composites.

- Tools and Components:

- Universal Testing Machine (UTM) components

- Hardness testers (Rockwell, Brinell)

- Sample materials (metals, polymers, composites)

- Microscopes (optical)

- Strain gauges

- Impact testers

- Metallurgical mounts

- Fracture analysis tools

- Description: Kits that include components like gears, shafts, bearings, and fasteners to design and test mechanical assemblies and systems. They may also include CAD files for 3D modeling.

- Common Uses: Prototyping mechanical systems, studying load distribution, stress analysis, and design optimization.

- Tools and Components:

- Gears (spur, helical, worm)

- Shafts and keys

- Bearings (ball, roller)

- Fasteners (bolts, nuts, washers)

- Sprockets and chains

- Couplings (rigid, flexible)

- Belts and pulleys

- Tolerance gauges and calipers

- Description: Kits focused on the principles of energy conversion, including components like solar panels, wind turbines, and small-scale engines. They are used to study and experiment with converting energy from one form to another.

- Common Uses: Experiments in renewable energy, studying thermodynamic cycles, efficiency analysis.

- Tools and Components:

- Small solar panels

- Wind turbine models

- Electric generators and motors

- Thermoelectric generators

- Batteries and energy storage devices

- Inverters and converters

- Energy meters and sensors

- Thermal engines (Stirling, steam)

- Description: Small-scale CNC kits that include a computer-controlled milling machine or lathe, along with the necessary software and tooling. These kits are used to introduce students and hobbyists to CNC machining.

- Common Uses: Prototyping, precision machining, learning CNC programming.

- Tools and Components:

- CNC milling machine or lathe

- Cutting tools (end mills, drill bits)

- Tool holders and collets

- Workholding devices (clamps, vises)

- Coolant system (basic)

- CAD/CAM software

- G-code generator

- Safety glasses and gloves

- Description: Kits that include a 3D printer and materials like PLA, ABS, or resin. These kits are used for prototyping and studying the principles of additive manufacturing.

- Common Uses: Rapid prototyping, custom part manufacturing, studying additive manufacturing processes.

- Tools and Components:

- 3D printer (FDM or resin)

- Filament or resin material

- Build plate and adhesives

- Nozzles and extruders

- CAD software

- Calibration tools (bed levelers, gauges)

- Scrapers and cutters (for part removal)

- UV light (for resin curing)

- Description: These kits include pumps, cylinders, valves, and actuators to demonstrate hydraulic and pneumatic systems. They are used to study the principles of fluid power and control.

- Common Uses: Building and controlling fluid power systems, studying hydraulic and pneumatic actuators.

- Tools and Components:

- Hydraulic pumps and cylinders

- Pneumatic actuators and valves

- Hoses and fittings

- Pressure gauges

- Flow control valves

- Reservoirs

- Compressors

- Control panels (manual or automated)

- Description: Kits designed to explore renewable energy technologies, often including small-scale solar panels, wind turbines, and associated measurement tools.

- Common Uses: Experiments in renewable energy generation, studying energy efficiency, and sustainability.

- Tools and Components:

- Small wind turbine blades and generator

- Solar panels

- Inverters and charge controllers

- Battery packs

- Energy meters

- Load resistors (for testing)

- Mounting hardware

- Simulation software (optional)

- Description: Kits that simulate automotive systems, including components like small engines, transmissions, braking systems, and suspension models.

- Common Uses: Studying vehicle dynamics, engine performance, and automotive systems design.

- Tools and Components:

- Small-scale engines (gasoline, electric)

- Transmission models

- Suspension systems (springs, dampers)

- Braking systems (disk, drum)

- Steering mechanisms Models

- Differential models

- Diagnostic tools (multi-meters, OBD scanners)

- Fuel and exhaust systems (carburetors, mufflers)

These kits are valuable resources for hands-on learning, experimentation, and the application of mechanical engineering principles in real-world scenarios.

Sustainability is a critical consideration across various fields of engineering due to the pressing need to balance development with environmental, economic, and social responsibilities. Here are several key areas of engineering where sustainability is a major focus:

- Sustainable Infrastructure: Designing and constructing buildings, bridges, roads, and other infrastructure to minimize environmental impact and maximize resource efficiency.

- Green Building: Implementing eco-friendly materials, energy-efficient systems, and sustainable construction practices.

- Water Management: Developing systems for efficient water use, wastewater treatment, and stormwater management to preserve water resources.

- Energy Efficiency: Designing machines and mechanical systems that use less energy and produce fewer emissions.

- Renewable Energy Technologies: Developing systems for wind, solar, hydro, and geothermal energy production.

- Sustainable Manufacturing: Creating manufacturing processes that reduce waste, use recycled materials, and minimize energy consumption.

- Energy Systems: Designing and improving the efficiency of electrical grids, renewable energy integration, and energy storage systems.

- Electronics Recycling: Developing methods to recycle electronic waste and reduce the environmental impact of electronic devices.

- Smart Grids: Implementing advanced grid technology to optimize electricity distribution and consumption.

- Green Chemistry: Designing chemical processes and products that reduce or eliminate hazardous substances.

- Sustainable Materials: Developing biodegradable and recyclable materials.

- Process Optimization: Improving industrial processes to use fewer resources and generate less waste.

- Pollution Control: Developing technologies and methods to reduce pollution and clean up contaminated environments.

- Waste Management: Designing systems for recycling, composting, and reducing landfill use.

- Resource Recovery: Creating processes to recover valuable resources from waste streams.

- Sustainable Transportation Systems: Designing and promoting public transportation, cycling, and pedestrian infrastructure.

- Electric and Hybrid Vehicles: Developing cleaner, more efficient vehicle technologies.

- Logistics Optimization: Improving supply chain and transportation logistics to reduce emissions and energy use.

- Energy-efficient Buildings: Designing buildings that minimize energy consumption through efficient HVAC systems, insulation, and passive solar design.

- Sustainable Urban Planning: Creating urban spaces that reduce environmental impact and improve quality of life.

- Renewable Energy Integration: Incorporating solar panels, wind turbines, and other renewable energy sources into building designs.

- Sustainable Materials: Developing new materials that are more environmentally friendly, such as biodegradable plastics and sustainable composites.

- Life Cycle Assessment: Evaluating the environmental impact of materials from production to disposal to promote sustainable choices.

- Recycling and Reuse: Innovating ways to recycle materials and extend their useful life.

- Sustainable Mining Practices: Developing methods to minimize environmental impact and restore ecosystems after mining operations.

- Resource Efficiency: Improving extraction techniques to use resources more efficiently and reduce waste.

- Environmental Impact Assessments: Conducting thorough assessments to understand and mitigate the impact of mining projects.

- Fuel Efficiency: Designing aircraft and spacecraft that use less fuel and produce fewer emissions.

- Sustainable Materials: Using lightweight, durable, and recyclable materials in aerospace design.

- Environmental Impact: Reducing the environmental impact of aerospace operations, including noise pollution and carbon emissions.

- Energy-efficient Computing: Developing software and systems that use less energy, such as optimizing algorithms and data centers.

- Sustainable IT Infrastructure: Designing data centers and IT infrastructure with reduced energy consumption and improved efficiency.

- Green Software Development: Creating software that promotes sustainable practices and reduces environmental impact.

In each of these areas, engineers are constantly exploring new ways to enhance sustainability, balancing technological advancement with the need to protect and preserve our environment for future generations.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)